Origins of the Waltham Model 57Evolution of the First Successful Industrialized Watchby Ron PriceCopyright © 1995-2025originally published 2005 by NAWCC as Special Order Supplement No. 7 Boston Watch CompanyThe use of automated machinery to turn out interchangeable parts for watches on a large scale was first achieved in America in 1850 by the Boston Watch Company, located in Roxbury, MA. Although Aaron L. Dennison, Edward Howard, David P. Davis, and Samuel Curtis were not the first people to employ the use of machines in making watch parts, through "Yankee ingenuity" they became the first to put the key elements together and start a major watch enterprise. (Davis had no active role [ref. 16, p. 924] other than being a business partner with Howard [ref. 13, p. 2] and co-owner of related real estate.) It is not clear how active a role Curtis had other than to provide the major financing, but in effect he became the sole owner of the company by 1857 after investing his personal fortune and then becoming insolvent [ref. 106, case 116, sheet 29, etc.]. Although Aaron Dennison and Edward Howard became acquainted in 1842 [ref. 13, p. 3] & [ref. 94, p. 67], it was not until years later (in 1849), when Howard was in Dennison's shop, that Dennison convinced him that making watches by machinery on the interchangeable system would be a better business opportunity than building locomotives, saying "that as a watch was only a clock on a small scale, his [Howard's] knowledge of the latter business would come finely into play" [ref. 39, p. 1 of letter]. Howard later recalled that they began these discussions around 1845 [ref. 94, p. 67]. Also see Howard and Dennison having same 1842 business adress in June 2007 NAWCC Bulletin, "Edward Howard's 1842 Tower Clock", pp 274-277 (page 276). Actually, Dennison first envisioned making cheap brass clocks incorporating his ideas for interchangeable parts around 1833 (a la Connecticut clocks). This was at the close of his apprenticeship with clockmaker James Cary of Brunswick, ME [ref. 95, p. 5]. Dennison then went to Boston and New York to broaden his knowledge of watch and clockmaking. While in the watch repair business in the 1840s, Dennison devised a size gauging system for filing and making watch parts. He decided on the large full plate English lever watch as his model for manufacturing watches on a large scale [ref. 38, pp. 2 and 3], perhaps modeled after the English Perry watch [ref. 16, p. 925] and [ref. 46, p. 16 or p. 7 of Dawes' version]. Dennison was further inspired by the production methods being practiced at the U.S. Armory in Springfield, MA, in 1845 [ref. 38, p. 4] and [ref. 47, p. 738].

Figure 1. Aaron Dennison (left, picture courtesy Philip Priestley) and Edward Howard (cover reference [ref.13]) Regarding the English Perry watch, contributor Michael Edidin sent a copy of an 1852 Bigelow Brothers & Kinnard newspaper ad in the Boston Daily Atlas advertising Robert Perry watches (see ad - center top "Silver Lever Watches"). Contributor Chris Carey and author found at the Harvard Baker Library Historical Collections a number of letters involving Robert Perry and shipments of Perry watches going to Bigelow where the supplier was Ellis Samuel Yates. Michael's comment: "It has always puzzled me that Howard and Dennison modeled their watch after a Perry (asserted by Crossman [ref. 46]), when so many other good English examples were available." Author's comment: "I doubt Crossman had evidence that Dennison actually modeled the Perry movement. I think he just based his statement on the fact that the Perry watch was popular at the time and was a good English example of a watch Dennison liked." Edidin has since found article in July 1895, "The Horological Journal", page 154 that Dennison told H. Ganney he "took" the design of the Joseph Johnson movement but replaced the fusse with going barrel. Several references indicate that Dennison might have purchased his initial watchmaking tools from the Pitkin brothers in the late 1840s [ref. 58, p. 28] & [ref. 28, p. 387] including material for a total of $6,500 [ref. 14, p. 589], but Hoke believes this assertion cannot be supported [ref. 60, p. 309]. No mention is made of this Pikin connection in two early references that likely would include such information; i.e., Dennison's papers [ref. 39] and William Keith's manuscript [ref. 94]. Indeed, Howard refers to the making of tools before the organization of the company to test Dennison's ideas, which later turned out to be unusable [ref. 94, pp. 67-73].

Eliashib Tracy says in [ref. 6, p. 274] that Samuel Curtis was Howard's father-in-law. Dr. Percy Small in [ref. 13, p. 8] refutes this statment because the names of Howard's three wives do not match. Howard did sign a surety bond for the probate of Curtis' estate in 1876 (Suffolk County Probate Docket No. 58154) which demonstrates a close relationship between Howard and Curtis. Tracy also said Curtis eventually "furnished" the company as much as "70 to 80,000 dollars", which seems high according to Curtis' census estate data. [Charles Moore in [ref 51, p11] also says Curtis was Howard's father-in-law, but gives no reference.] Curtis was a well-known painter of clock dials and tablets in the early 1800s, and became a very successful manufacturer of looking glasses (mirrors) and frames. [See Willard's Patent TimePieces by Paul Foley, 2002, page 237.] Samuel was 70 years old in this portrait taken in 1855; there is a similar daguerreotype of his wife. [Credit: Historic New England, GUSN-253745 DagID 272, Reference Code PC005.D02.042] The business name was changed to ''Warren Manufacturing Company" a few months later to make the intent of the firm less obvious [ref. 94, pp. 69-71] & [ref. 47, pp. 739-740]. A small parcel of land (50 x 125 feet) was purchased by Howard and Davis for a new factory on the corner of East (now Hampden) and Prescott Streets in Roxbury, MA, on November 1, 1850 [ref. 106, deeds, Norfolk, book 198, pp. 119 and 120]. This lot was located cater-cornered from the grounds of the Howard & Davis Clock and Balance factory between East and Yeoman Streets purchased June 1, 1846 [r106 Deeds, Norfolk, Book 169, pp. 211 & 222].

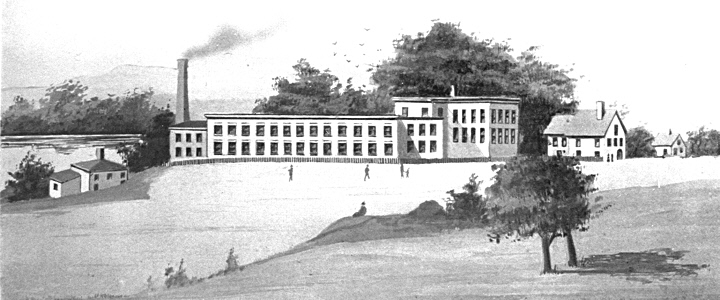

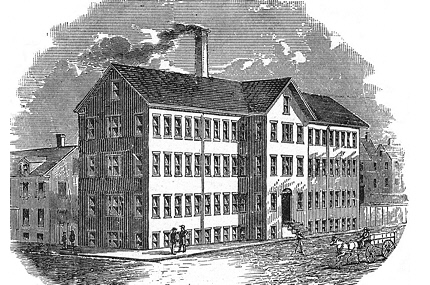

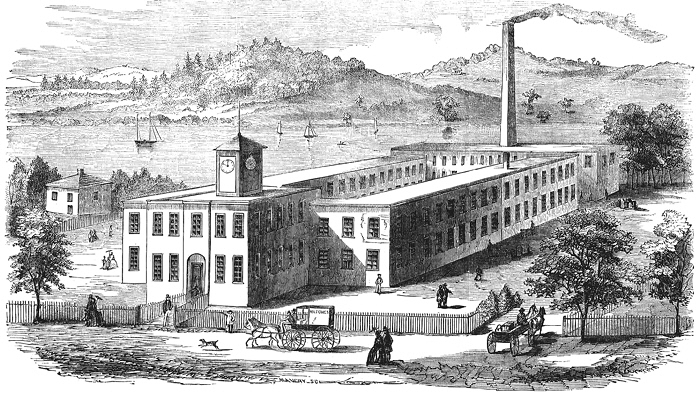

Figure 2. The First Watch Factory In America (Sketch from Dawes’ update of [ref. 46, p. 7] ) According to Howard, while the factory was being constructed, Dennison traveled to England to learn information on how to perfect the business, particularly the process of frosting and gilding movement parts [ref. 94, pp. 69-71]. Marsh says one of Dennison’s objectives was to make arrangements for the purchase of supplies that could not be readily procured in America such as enamels and jewels [ref. 51, p. 14]. Marsh makes no mention of the need to learn the gilding process; Hauptman does in [ref. 16, p. 925], and adds dial making and fabricating of hair-springs and mainsprings. Dennison’s first model, completed in the summer of 1851, was equipped with a large barrel in an attempt to run it eight days, but the time rate between high and low windings of the mainspring proved too variable [ref.16, p. 926]. The movement designers probably struggled with this first model because Marsh says several reproductions were made [ref. 48, p. 9]. N.P. Stratton, an apprentice of the Pitkin brothers, convinced Dennison to convert to the one-day (30 hour) watch; he was also able to utilize the existing 8-day material [ref. 46, p. 17]. Wesley Hauptman sets this timeframe as very early 1852 [ref. 16, p. 926].

The Howard, Davis & Dennison WatchWhile the 30-hour watch was being built, Dennison continued to pursue the idea of producing an 8-day watch. With Howard's agreement, in the fall of 1852 O. B. Marsh and his brother D. S. Marsh were assigned to model a new watch with two large mainspring barrels. This watch, reported 20-size (surviving examples are closer to 22-size), turned out to be a good timekeeper, and perhaps 19 were made, including two models kept by the Marsh brothers. These watches (probably serial numbers 1-15) were engraved "Howard, Davis & Dennison" [ref. 2], [ref. 3] and [ref. 97, p. 564]. Serial numbers 16 and 17 were engraved "D. B. Fitts, Holliston, Mass." [ref. 3]; picture of Fitts #16 can be seen at NAWCC Musuem, catalog #BS27.77. Dennison finally had to admit, however, that these watches would be too expensive to produce for a reasonable market, and the 8-day watch was abandoned [ref. 16, pp. 929-930]. Jim West [ref. 97, p. 564] offers additional explanations. The custom-designed model HD&D No.3 (on the left) differs in many respects from the subsequent production watches made by the BWCo It is oversize, approximately 22-size (49.5mm), to accommodate two large mainspring barrels as well as an extra wheel and pinion to run them. It is geared to run at 14,400 beats per hour and is probably fitted with stop-work barrels. The jewel settings are secured with two screws (as opposed to three on the 30-hour watches); and the center wheel is jeweled on the top plate. The hairspring is under-sprung with a solid balance like the later production models, presumably to reduce costs, whereas the original eight-day model was oversprung with an expansion balance. This movement has a gold balance. It is key set from the front. It is housed in an 18K FD&Co. hunting case with matching No.3. Photo courtesy Don Wing. The Henry Ford Museum traded the right pictured No. 2 movement to the Waltham Watch Company in exchange for the D. S. Marsh prototype movement (see Preface and [ref. 97, p. 564]). Photograph courtesy Charles River Museum of Industry. In Keith's manuscript [ref. 94, pp. 75-76] Howard says that Dennison was unable to complete the gilding process that he had supposedly learned in England. Unable to find anyone in America with this knowledge, the company sent N. P. Stratton to Coventry, England, to learn it. Stratton might have been familiar with the fire-gilding process used by the Pitkin brothers in Hartford, CT, where they produced perhaps 400 to 800 watches [ref. 96, p. 256], but the English electro gilding method was superior. Stratton discovered the problem they were having with the process and returned in November 1852. The eight-day models were completed, and the factory proceeded with its first commercial watch [ref. 16, p. 930].

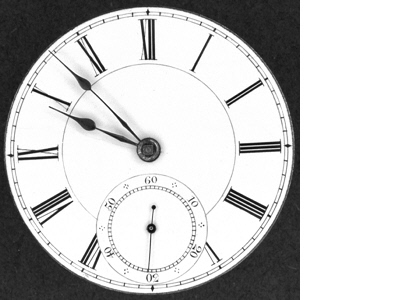

The Warren WatchProduction at Roxbury began in the spring of 1853 with 30-hour, 15-jewel watches, which sold retail for $40 in a silver case [ref. 16, p. 931]. The first 80 or so movements were inscribed "Warren," in tribute to the famous General Joseph Warren whose birthplace was near the factory site [ref. 16, p. 925]. These were probably Nos. 18-100, although examples with serial numbers above 44 have [not] yet been reported [ref. 2]. These watches were full-plate with four pillars and had an English appearance, with large clear aquamarine jewels [ref. 46]. The train was slow, 14,400 beats per hour, like the English watches. These watches had a going barrel, different from the typical verge fusee English watch [ref. 48, p. 9]. The going barrel was simpler to manufacture than the fusee and chain [ref. 60, p. 22]. The escape wheels had pointed ratchet teeth. An English-style lever escapement was used, with the pallets mounted at a right angle to the lever. See description of jewels and escapements in the next chapter. For an example picture of a Warren, movement #31 was sold at Sotheby's on April 10, 2015.

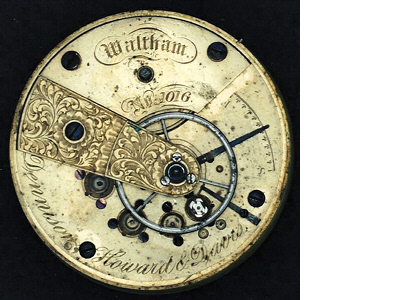

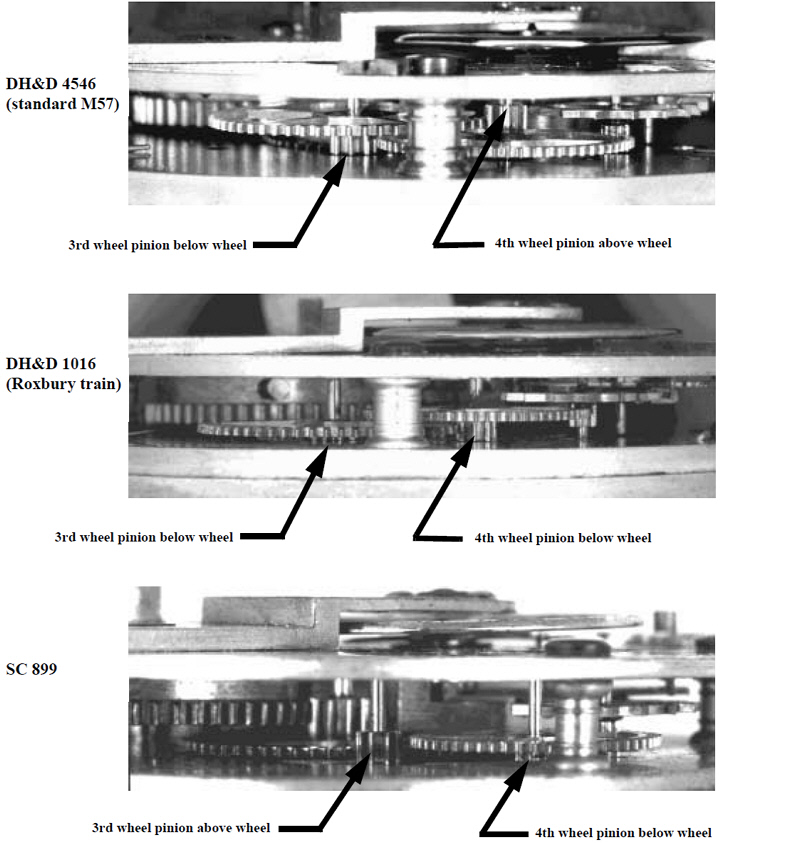

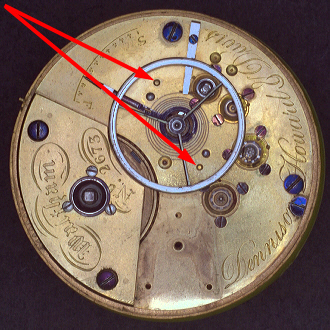

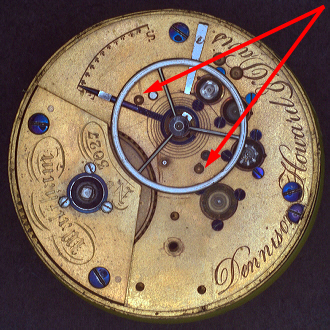

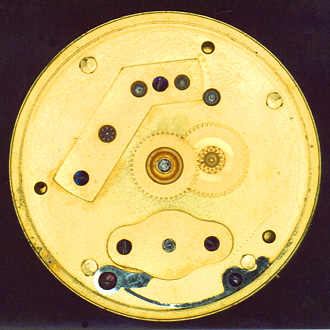

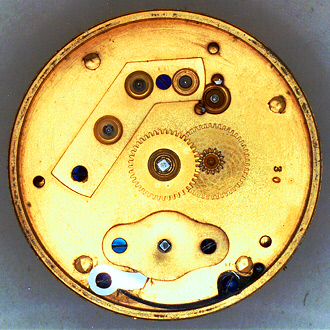

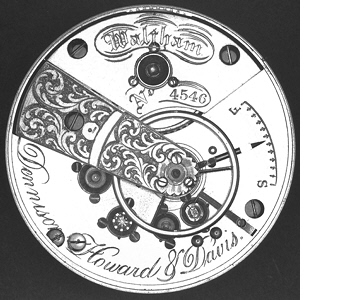

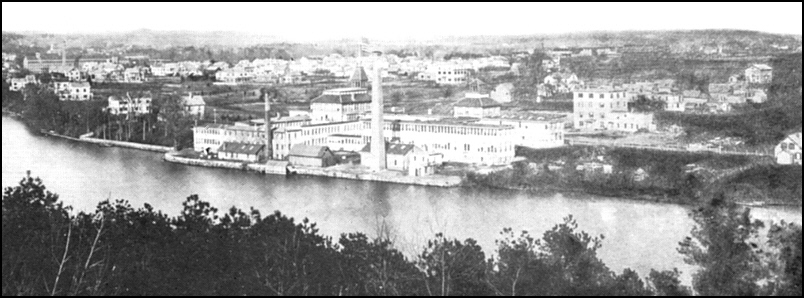

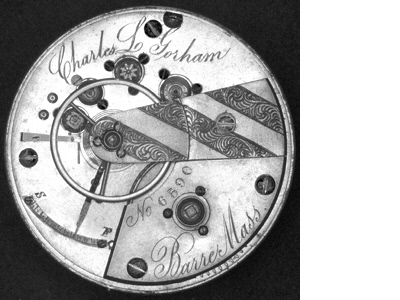

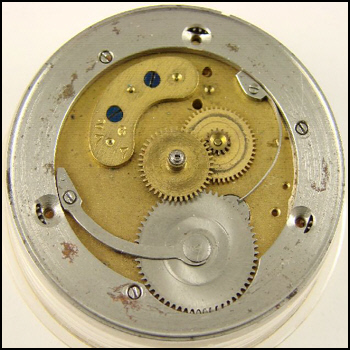

The Samuel Curtis WatchAfter the first run, about 900 more watches were produced in Roxbury. These movements (probably serial numbers 101-1,000) [ref. 2] were engraved "Samuel Curtis" in honor of the man who had furnished the bulk of the initial capital for the company. At this time the firm began producing its own cases. Like English cases, cases for the Samuel Curtis watch were smaller than the current standard 18S to accommodate the smaller back plate. Indeed, if there is no space between the back plate of a Samuel Curtis movement and the case, you can almost be certain the case is original, or at least representative [ref. 16, p. 931]. Figure 4. Warren No. 44 (left) and Samuel Curtis No. 899 (right) Photo by Jim Michaels of Bob Ravel’s Warren #44 courtesy of The Watch and Clock Museum of The NAWCC. From the beginning, the officers of the Warren Manufacturing Company had referred to their firm as the Boston Watch Company (BWCo). Now, no longer having to conceal the company's true name and watch-making intent from the English firms that had supplied them with materials, they had the name of the company officially changed [ref. 16, p. 931], perhaps in September of 1853, according to Bolino [ref. 58, p. 73]. Desiring to escape the extremely dusty conditions at the Roxbury factory, and planning for future expansion where employees could have comfortable homes, the company now undertook construction of a modern factory on the Charles River in Waltham, MA [ref. 47, p. 740]. According to Marsh and other references, the new factory was ready for occupancy in October 1854 [ref. 47, p. 40]. As with the sequence of dates with the Roxbury factory, the Waltham property was not deeded until after construction was completed (November 20, 1854) [ref. 106, deeds, Middlesex, book 698, p. 465], apparently common practice in the 1850s. The sequence of events by which Aaron Dennison learned of the Waltham property and acquired it for the factory with William H. Keith's instrumental assistance is an interesting story in its own right, and an important phase in the company's history. Although too complex to be recounted in detail here, the ingenious maneuvering involved establishing a land company, the Waltham Improvement Company (WICo.), with legislative approval in March 1854, which allocated a portion of its land holdings for the factory and the rest for land development; see [ref. 16, p. 933], [ref. 47, p. 740], [ref. 48, pp. 11-14], and [ref. 94, pp. 83-104]. The Waltham Improvement Company deeded property to the BWCo on three occasions with the Improvement Company holding mortgages: Nov. 20, 1854; Nov. 1, 1855, and July 15, 1856 [ref. 106 Deeds, Middlesex, Book 698, pages 465 & 468; Book 729, page 9; Book 736 page 371; Book 749, pages 52 & 54]. {Author’s note: Various principals, family members, and associates of the company bought stock in the land company and plots of land from it. Although the BWCo eventually failed, The Waltham Improvement Company survived and its property became very valuable. While historians record personal losses as a result of the failure of the BWCo, it would be interesting to investigate to see if any of the early investors achieved financial rewards from their land holdings. Aaron Dennison, for example, bought stock in WICo and used its profits to fund his later venture at Tremont Watch Co. [ref. 37, p. 3].} Above is an anonymous artist rendition of the Boston Watch Co factory at Waltham as it looked shortly after it opened in 1854 [ref. 16, p. 934]. When fully operational at Waltham, the BWCo had 75 employees producing about ten to twelve watches per day [ref. 23 p. 144]. M. Cutmore says in [ref. 59, p. 28] that BWCo’s production rate was only about half of that achieved in Switzerland at that time by traditional methods. Basing his conclusion on modern analysis, however, contributor Mike Harrold (MA) believes the BWCo was already outperforming the Swiss and had demonstrated the success of industrial watchmaking [ref. 63]. The Dennison, Howard & Davis WatchAll of the watches produced at Waltham by the Boston Watch Co. were engraved "Dennison, Howard & Davis" (DH&D), except perhaps 100 movements marked "Fellows & Schell" in the name of the watch wholesalers who helped finance the new operation with $20,000 [ref.16, pp. 935-936] ($1,636.84 owed as creditors at the later insolvency of the company [ref. 106, Case 116, Sheet 110]), although no such Fellows & Schell examples have yet surfaced publicly (other than a fake seen by author). DH&D serial numbers range from 1001 to 5000 (#5000 is a new design). The Dennison, Howard & Davis movement was the forerunner of and quite similar to the so-called "Model 57." Even in the beginning, the focus was on interchangeable parts, “... so that any movement would fit any case, and any part of one movement could be interchanged with any other.” [ref. 94, pp. 73-74]; records were kept by serial numbers so that parts on broken watches could be easily replaced [ref.16, p. 939] (although Hoke points out interchangeability was not fully achieved with many parts [ref. 60, pp. 24 & 244-245], and that adjusting a high grade movement could take five months [ref. 60, p. 224]; also, Howard admitted in a letter that “interchangeability of parts,..., was not found to be practicable in the finer parts...” [ref. 94, pp. 73-74] & [ref. 13, p. 13]). As explained below, author believes the early DH&D movement on left in above figure (S/N 1016) might have actually been made at the Roxbury plant and not at Waltham. Note the addition of the key guard cup around the winding square on later movement (S/N 2673). The steel guard cup was applied to the DH&D top plate some time between serial numbers 1585 and 1657 according to the DH&D data table at end of this monograph (and see this and other feature changes in Table 1 later). Not wanting to use English cases any longer, and seeking the convenience of a wider opening, Dennison made the back plate on the DH&D movement 2/30ths larger than the Samuel Curtis watch which became the standard 18 size [ref. 16, p. 936]. There might have been considerable variance with plate sizes in the early days. People report various sizes up to 20S, perhaps not realizing that the standard 18S actually measures 19S according to Dennison’s formula [ref. 26]. Hoke lists sizes ranging from 18S to 20S in the Time Museum catalog [ref. 61], which were obtained during a quick examination conducted in the early 1980s. Patricia H. Atwood, Executive Director for The Time Museum, reported they subsequently resized their collection and the movements in question all measured approximately 18S. In the author’s collection, all measure nearly the same, including (for the most part) the set and wind squares; see sample plate measurements in the data tables at the end of this monograph. The DH&D also differs from the Samuel Curtis in the train and pillar arrangements. The third wheel is below the center and fourth wheels on the Samuel Curtis like the English watch of its day; this arrangement was reversed on the DH&D watch (and standard Model 57s). On standard M57s the 4th wheel pinion is located between the wheel and the back plate, whereas on the Samuel Curtis this pinion is in the pillar plate (see Figure 7 below). Crossman [ref. 46, p. 17] mentions this raising of the third wheel when describing the early movements, but he gives no rationale for the change (although it must have simplified the manufacture of the pillar plate). This change was apparently introduced in a transitional manner because the train arrangement on the first several hundred DH&D movements is different from both the Samuel Curtis and standard Model 57; i.e., its fourth, third, and center wheels are stacked above one and another, and the center wheel, which is solid, is buried in the pillar plate (see Figure 7 below and data tables herein). This observation is consistent with Marsh’s statement in [ref. 48, p. 15] that the first “few hundred movements had been started in the Roxbury plant”. Author refers to this transitional layout as the Roxbury Train.

On the Samuel Curtis there is a pillar under the balance bridge, whereas on the DH&D and standard M57s it is located under the edge of the barrel plate (perhaps this is a consequence of the smaller back plate).There is also a pillar nearly opposite from the balance bridge on the DH&D (and M57s) at about 11:55 position with the base of the bridge at 6:00, but on the Samuel Curtis this pillar is located at 12:30 (which can be observed by looking at the screws on the back plate; see pictures above. Just to be complete, the position of the train is also a little different between the DH&D and Samuel Curtis movements; e.g., the distance between centers of the balance staff and the winding square on the Samuel Curtis is 15.2mm whereas on the DH&D (and M57) it is 16.5mm. On the other hand, the position of the key hole on the cases is the same. The train was geared for 16,200 beats per hour (4.5 per second) on the DH&D, faster than the slow English train of 14,400 beats per hour (4 per second), but still slower than 18,000 beats per hour (5 per second) which became the standard later (see section on train speed in next chapter). According to Kleeb [ref. 12], Aaron Dennison brought a jewel maker (Sibley) back from England in 1850 during his trip to purchase materials. However, jewel making at the factory was abandoned in 1852 until about 1855 when a new jewel maker was hired (Sherwood). The new jewels were similar in appearance to the early imported aquamarine jewels (basically colorless to pale blue-green); they were made from beryl and chrysoberyl [ref.12, p. 197]. DH&D movements introduced several feature changes in addition to the train during its production lifetime, including wind guard (mentioned above with Figure 6), “peep holes” in the pillar plate, and potance that holds the bottom balance arbor. Contributor Michael Edidin (MD) brought to the attention of the author the observation that the method of attaching DH&D potances changed from earlier versions to later ones. The 'U-Bridge' shape potance (some people call it the "butterfly potance"), is illustrated in Figure 60 in the next chapter (on Model 57 AT&Co S/N 6669). As shown in Figure 9 below, a screw in the center of each foot of the potance attaches the potance to the movement. The potance also has a steady pin on each foot that protrudes through the top plate along with the screw hole as can be seen in Figure 9. The original, old fastening method locates the steady pins on opposite corners whereas the new style has the steady pins on the same edge.

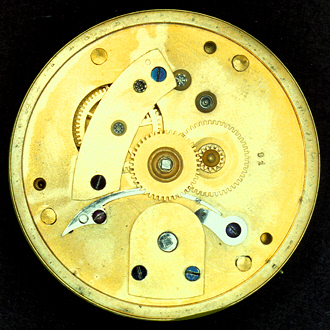

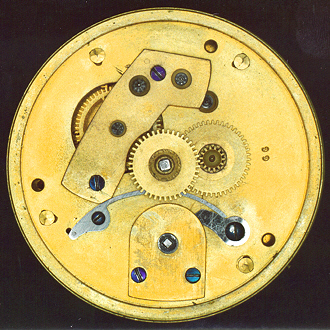

Figure 10. Progression of Pillar Plates on the Samuel Curtis and DH&D movements The progression of pillar plates on the Samuel Curtis and Dennison, Howard & Davis movements is shown in Figure 10 above (follow sequence SC 212 - SC 899 - DH&D 1016 - DH&D 3730). Note that the third bridge supports three arbors on the later Curtis and is straightened out on the DH&D. Also note the stronger oblong ratchet bridge on the DH&D, and the later versions have “peep holes” in the pillar plate so the escapement can be seen in motion. The table below documents by serial number according to the data table at end of this monograph when design changes were made to DH&D movements. Table 1. Introduction of DH&D Design Changes

DH&D movements were basically produced in 7 and 15 jewel versions (a few 11-jewel movements were reported). Although movements produced by the companies that followed BWCo had 16 jewels (center arbor on pillar plate), no DH&D has yet been reported as having 16 jewels. Maybe one will show up some day, perhaps with high serial number (e.g., above 4900). Or perhaps material planned for serial numbers over 5000 which were not produced was intended to be 16 jewels. Although the Tracy Baker Sales records do list several 16J DH&D movements (e.g., S/Ns 4161-4170) [ref. 55, p. 24], the author believes this data is misleading (see explanation in table in [ref. 102]), Sales Records.

The BankruptcyAlthough the Boston Watch Company was advertising their DH&D watches in October of 1856 (e.g., Charleston Mercury newspaper ad found by Michael Edidin), the company met with hard financial times that year. The machines made in Roxbury were wearing out faster than expected, and the factory's retooling efforts were eating away production profits [ref. 16, p. 937], as were many other factors [ref. 65, May 22,1857]. Indeed, the whole country was facing a "universal financial panic" at this time [ref. 48, p. 20]. Dennison was critical of Howard and Davis for using company funds to engage in unrelated manufacturing efforts (e.g., sewing machines) [ref. 6, p. 274]. Howard, in turn, was critical of Dennison's ineptness as superintendent of the factory [ref. 13, p.11]. Whatever the reasons, in the end it was the Waltham Improvement Company that pushed the Boston Watch Company into bankruptcy (in 1857 the legal term for this condition was "insolvency"). The watch company defaulted on notes to the Waltham Bank that the Waltham Improvement Company was guaranteeing; their property insurance had expired; and they owed property taxes. Consequently, on February 28, 1857, the directors of the improvement company moved to foreclose their mortgaged properties [ref. 94, pp. 116-117]; this was done on March 3 (see previously referenced deeds) [ref. 106 Deeds , Middlesex, Book 749, pp. 52&54]. The Boston Watch Company pursued two refinancing attempts, but to no avail [ref. 94, pp. 79-80]. Having no other recourse, the company's officers filed petitions for insolvency on April 15, 1857 [ref. 106, sheet 1; case 116 for Curtis, case 117 for Davis, case 118 for Howard, and case 119 for Dennison]. An "assignee," Nathan W. C. Jameson, a merchant in Antrim, NH, was appointed on April 16, 1857, for Dennison, Howard, and Curtis holdings in Waltham [ref. 106, deeds, Middlesex, book 768, pp. 7-9] and for Howard and Davis holdings in Roxbury [ref. 106, deeds, Norfolk, book 274, page 211]. Strangely, the latter record was not recorded until March 26, 1859; however, the court made William B. Fessenden the "assignee" for the two Roxbury factory properties on June 16, 1857 [ref. 106, Curtis, sheet 98]. Several references incorrectly state that Charles Rice was the assignee; e.g., Crossman [ref. 46, p. 25], Hauptman [ref. 16, p. 938], and even Robbins himself, in a speech at the AWWCo Factory Foremen's Dinner in Boston, January 6, 1883 [ref. 48, p. 21; full speech available from the Waltham Historical Society]. It is interesting to note that an advertisement for the watch company as "Manufacturers Dennison, Howard and Davis" appeared in a Boston newspaper as late as April 14, 1857 [ref. 106, Post]. The same ad was previously posted nearly weekly in this daily paper. The existence of the ad gives indication of some operational status of the company to the bitter end. Moving quickly, Jameson advertised the insolvency in two Boston newspapers on April 16 as ordered by the court and called for the first meeting of creditors to be held on April 29 [ref. 106, Advertiser (BDA1)]. During the first week of May, Jameson advertised the pending auction of the Waltham Watch Factory at 10am Saturday May 9 [ref. 106, Advertiser (DBA2)] ; e.g., see scan of ad. Crossman mistakenly wrote the sale date as April 9 [ref. 46, p. 39]. References in the literature refer to the sale as a "sheriff sale," but according to newspaper articles it was actually run by a prominent Boston auctioneer, N. A. Thompson, and referred to as an "assignee sale" [ref. 106, Herald and Transcript]. Both Howard and Dennison independently looked for investors. Howard teamed up with Charles Rice who was helping with late financing [ref. 13, p. 10]. Dennison contacted Eliashib Tracy and Theodore Baker, who had prior dealings with the company in watch wholesaling and cases. The watch company owed them (the firm Tracy & Baker of Philadelphia) quite a bit of money for gold cases. Dennison talked Tracy and Baker into the deal, but Tracy, not wanting to go it alone, in turn contacted Royal E. Robbins and got him to join the venture (and to actually put up most of the capital) [ref. 6, p. 274]. Robbins was actually an investor in Tracy & Baker Co. [ref. 46, article 32 on watchcase making in the Jewelers' Circular and Horological Review; also Dawes' update page 80], and claimed he originally was acting as an agent for Tracy & Baker Co. and did not intend to run the company [ref. 48, p. 21 in speech]. Robbins outbid Rice for the company's assets. The bid (actually two items) was $8,500 for the real estate and buildings, and $33,000 for the factory contents. Robbins also assumed two mortgages amounting to $14,380 in liabilities [ref. 51, pp. 28, 38, and 314]; also see [ref. 46, p. 12] for additional details of the property (e.g., "boarding house, grocery store," etc.). Interestingly the newspaper articles report a lower number for the contents of the factory, $29,000; e.g., see scan of the Boston Evening Transcript article (more will be said about this later). As a point of reference, Keith says that at the time of the bankruptcy the company estimated their investments at $150,000 and their shrinkage at $90,000 [ref. 94, p. 56]. This seems low because the Insolvency Court recording of Curtis' debts totaled $173,505.44 [ref. 106, case 116, sheet 29, etc.]. Howard and Rice had expected to acquire the factory at a bargain price and shed of its liabilities, so the Tracy, Baker, and Robbins deal probably took them by surprise. Even Tracy said Robbins was not known to them, and that Robbins and he attended the auction separately and bid separately [ref. 6, p. 275]. Howard and Rice might have been suspicious, though, or at least wanted to cover their bets, because they removed inventory from the factory and was accused of doing so even the night before the sale. They were challenged in court to describe the details of the inventory they had removed and what right they had to remove it [ref. 106, case 116, sheet 153]; and [case 118, sheet 56]. Surely the bidders would have been given access to thoroughly inspect the factory the day before the sale which was in the morning. Actually the accusation included the possibility that the property was taken after the sale, perhaps in case it was done after the inspection (apparently Robbins and company didn't secure the factory after the sale). Supposedly Rice had secured a chattel mortgage with this inventory [ref. 6, p. 274]. Howard, wanting to continue the watchmaking business, made an arrangement with Rice to use the inventory under his management [ref. 13, p.10].

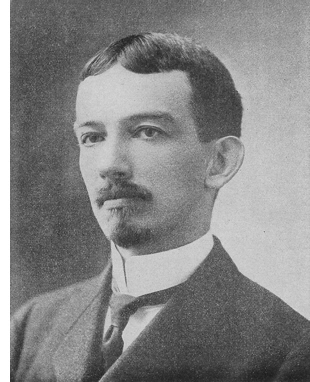

Charles Moore in "Timing A Century" [ref. 51, opposite page 26] has a nice portrait of Royal Elisha Robbins. This portrait from Henry Abbott's History of the AWWCo [ref. 49, p. 57], is actually of the son Royal Robbins, and not the senior as previously written here and corrected by contributor Jon Selles. Abbott does show both portraits. Royal succeeded his father as treasurer in July of 1902 when his father died. On February 2, 1857, an inventory was taken of the contents of the BWCo factory. Author guesses this inventory was requested by Rice because he used the inventory as collateral for the loan he gave the company. Fortunately for us, this inventory was written in a detailed document which was submitted in an insolvency court case after the auction. The document survived in court archives [ref. 106, case 116, sheet 153]. An image of the first page is here. It is not easy to read these original documents, especially from the photographs. Contributor Richard Watkins transcribed them, which made their study easier. Here is scan of the top part of first page of Richard’s inventory document (click for full page). There are three pages in total. Richard Watkins transcriptions in Cook Rice and Potatoes (http://www.watkinsr.id.au/CookRicePotatoes.html); inventory is Appendix 1. The inventory consisted of a vast amount of watch parts (many tens of thousands of individual pieces), around 100 partial movements and 1,170 frames that could be completed into finished movements fairly quickly. Frames were partially finished pairs of plates apparently already stamped with serial numbers. The term “frames” must have included their attached parts like pillars, barrel bridge, balance bridge, potance and third-wheel bridge because these parts were not otherwise listed in the parts inventory. Also apparently, the parts were screwed together because plate screws were not listed in the inventory (screws for jewel settings were listed). In other words, a frame is the structural component of a movement. The time frame “fairly quickly” is relative because there were not enough other parts like wheels, jewels and escapements that had to be made to complete 1,170 movements. Nevertheless, the large number of leftover frames is significant, especially because they consist of plates with their attached parts.We can expect various items would have been added to and taken from the inventory during the three-month period up to the auction of the company on May 9, but activity in the factory had to have been highly curtailed in this period, if not shut down, because officers of the company filed petitions for insolvency in court a month earlier on April 15. Moreover, the WICo foreclosed the mortgaged BWCo properties two months earlier on March 3. Consequently, author believes this February 2 inventory is a valid estimate of the material that existed on May 9, not necessarily the same material, but the same amount. It is important to note that the inventory document is titled “account of stock in workmen’s hands.” This inventory was just for works in progress, not completed products. Although balance springs and mainsprings, for example, are certainly key parts in movements, they are not listed in the inventory. Apparently, these parts were not made by “workmen in the factory” and were probably purchased and stored in a safe or locked office area that did not get documented in the insolvency papers. Ditto for dials. Completed movements to be sold were probably also stored in this secured area. According to Crossman, Rice claimed ownership under his trusteeship with the company which preceded the failure [ref. 46, p. 38]. E. Tracy says in reference [ref. 6, p. 275] that Robbins offered Rice $10,000+ for the material that Rice took for his chattel mortgage, but Rice wanted $15,000 which Robbins thought was too much. The inventory was actually worth $7,500 according to an insolvency document [ref. 106, Case 116, Sheet 153], but Robbins might not have had access to this document when negotiating with Rice. Hawkins said Robbins sued Rice for the return of material, some of which was returned [ref. 54] & [ref. 55]; however, the source of Hawkins’ reference is unconfirmed. Although Rice claimed ownership of the inventory, surely he could not have had rights to any inventory left in the factory because all mortgages and leases would have been resolved by the insolvency assignee before the sale. The assignee, Nathan Jameson, later listed Rice a creditor and owed a lot of money, much more than even the value of the February 2 inventory. There is some evidence, although not clearly documented in the literature as previously mentioned, that Robbins bought back some of the material from Rice to save time instead of fighting Rice in court. In [ref. 51, p. 315], Charles Moore lists Tracy Baker & Co.’s May 1857, cashbook, with an expense of $2,359.82 for “material & work not finished”. Although not stated, the seller was undoubtedly Rice. The amount of this “expense” was 1/3 of the February 2 inventory value minus the silver, which could have included hundreds of frames listed at $0.42 each. Where else was Robbins going to get a lot of usable watch parts in May of ‘57? The news articles on the sale reported that the new company "will carry on the [watchmaking] business on an extensive scale, as soon as the present lease to Mr. Charles Rice expires." The lease is mentioned in the insolvency interrogatories where the WICo leased the factory to Rice in March [ref. 106, case 116, sheet 153, Item 13]. However, one would think that the lease would have been terminated by the time of the sale. Again as noted in the insolvency papers [ref. 106, case 116, sheet 139], there is a $4,000 discrepancy between the amount Robbins recorded he paid for the factory and the amount the "assignee" recorded he received for the factory. This author wonders if Robbins paid off some of the debt to the WICo which was listed as a creditor for $6,000 [ref. 106, case 116, sheet 3] see scan (10th line down). This debt would not have otherwise been paid until much later (September) and only at $0.20 on the dollar [ref. 106, case 116, sheet 164]. It is not clear exactly when Robbins got the business going again, but it must not have taken very long. An article in the Waltham Sentinel, May 22, 1857 [ref. 65], reported on a meeting held earlier in the week to see what employees would pledge themselves to Howard starting up his own company. On May 23,1857, in the Tracy Baker & Co. cash book, there is an entry: "Manuf. charges Pd. hands to date $822.90" [ref. 51, p. 315]. According to sales records [ref. 62, p. 3], the first watches sold were DH&Ds on June 30,1857, that came with the factory. Also see Hawkins, [ref. 55, p. 22]. Actual production began in July, see Tracy Baker & Co below.

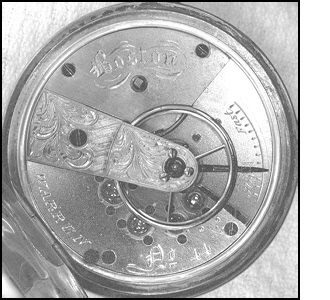

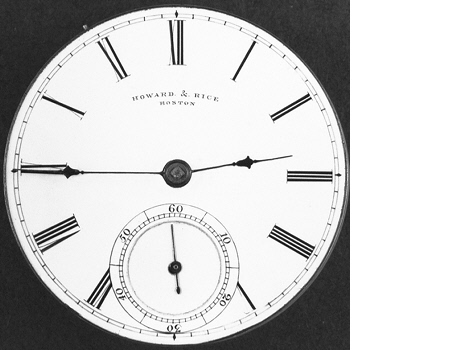

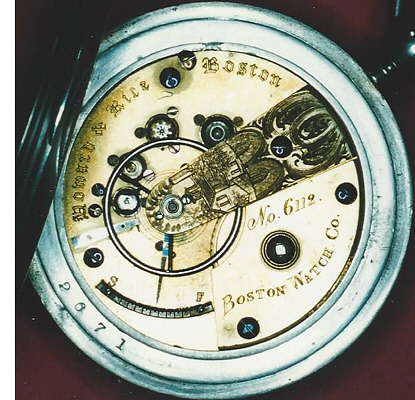

The Howard & Rice WatchHoward returned to the Roxbury plant along with some 15 workmen, where, working for Rice's interests, he kept the Boston Watch Company name and completed about 500 watches. These watches were a variant of the DH&D design (and Model 57 movement). They were engraved "Howard & Rice, Boston Watch Co.," or just "Boston" [ref. 16, p. 940]. But also see E. Howard & Co. watches listed in the data table at the end of this monograph that are equivalent to Howard & Rice movements. The existence of E. Howard & Co. dials on Howard & Rice movements, and E. Howard & Co. signature movements based on the Model 57 design, might signify a transitional period when Howard completed his settlement with Rice on December 11, 1858, and formed his own firm, E. Howard & Co. [ref. 13, p. 10]. The 1858 settlement probably did not include the real estate because there is no such record in the Norfolk County Registry of Deeds except for the much later sale (Rice to Howard, on April 30, 1861) of the East & Prescott property [ref. 106, Norfolk, book 298, pp. 92 and 93]. This property had previously been transferred to Rice by Fessenden on March 9, 1859 [ref. 106, Norfolk, book 274, p. 258].

The author's data records confirm that about 500 Howard & Rice-styled watches were made as reported in the literature. The survival rate for the Howard & Rice (H&R) watches in the data tables at the end of this monograph agrees with the survival rate of the Samuel Curtis and the Dennison, Howard & Davis watches [ref. 101]. As previously stated, according to insolvency court documents, Charles Rice, probably with help, was accused of taking material out of the factory. The accusation is item number 20 of [Ref. 106, case 116, sheet 153]. Of particular note is that Rice was specifically accused of taking 20 movements numbered 4891-4910. [So, the company had manufactured just 90 short of 4,000 DH&D movements.] Howard cannibalized these and other movements, and incorporated leftover frames from inventory (plus cases) to make his famed H&R watches. This is verified in the Reference section, "Serial Number Under Top Plate" [ref. 103]. Although based on the Dennison Howard & Davis design, the Howard & Rice movement differs in many ways. (See the description of the H&R escapement in the next chapter.)

Interestingly, contributor Ray Tyulty came across original Howard material some time ago that contained a supply of strange-looking regulators. He sent one to the author - and it matches this H&R regulator perfectly! The regulator arm on H&R S/N 6011 is particularly interesting because it has a screw with a nonconcentric head on the arm for one of the curb pins. The screw is turned against the other curb pin to grasp the hairspring (see picture). The pointer end is also nicely ground down underneath to ride over the index strip. Figure 12. Howard & Rice regulator on S/N 6011 A few other noteworthy differences on the H&R (see data table) include:

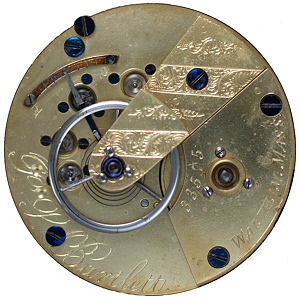

Note two cap jewel setting screws and bushing for winding square guard cup on H&R 6112 shown to the right. The balance bridge has engraving of the factory. Photo permission of Charles Wallace. Figure 13. Howard & Rice S/N 6112

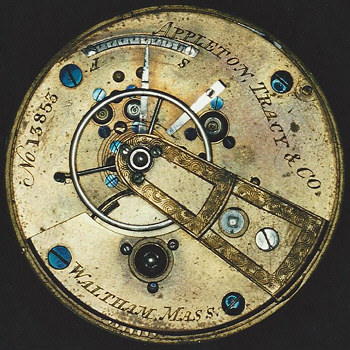

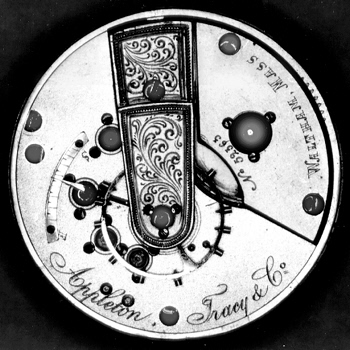

Tracy Baker & Company/Appleton Tracy & CompanyFor the first couple of months, Robbins used the name Tracy Baker & Company for his new enterprise. Then Baker sold his interest to Robbins on June 30, 1857, due to a disagreement on copartnership terms, and James W. Appleton was brought on for his influential contacts [ref. 15, pp. 690-692]. Baker might also have been in financial trouble because on the same day Robbins bought two large parcels of land from Baker per Moore's book [ref. 51, p. 25 ] {Moore's reference for this statement is Robbins' cash book and journal: DF-1, V.150, 1857-1860, "R.E.&. No.1 Cash Book," at the Baker Library, Harvard Business School.} Tracy wrote that he left in the fall of 1857 to attend to his watchcase business in Philadelphia, but that he continued to hold his interest in the company for many years thereafter [ref. 6, p. 276]. However, a statement by Moore in Robbins' cash and journal book indicates that Robbins bought Tracy out on September 8, 1858 [ref. 51, p. 317]. Tracy's name was kept in the title of the company, Appleton Tracy & Company (AT&Co). The Appleton Tracy & Company name was adopted on September 1, 1857, according to Marsh [ref. 48, p. 23]. However, this may have simply been an official date, because the name change was reported on July 17, 1857, in the Waltham Sentinel [ref. 65]. Movements were engraved "AT&Co" starting in July 1857 per the serial number ledger "Record of Watches" [ref. 1]. When Dennison got Tracy and Baker to bid at the insolvency auction, he apparently had some arrangement with them for his financial benefit if they were successful. About three weeks after the auction, Dennison was sent off to England to purchase material. Robbins didn't accept the prior deal, if he was even aware of it, so Dennison was probably devastated when he returned in September 1857 to learn that he would be superintendent of the factory at a salary of $1,000. Dennison renegotiated with Robbins and eventually accepted $2,500 per annum. {References for this paragraph are: [ref. 6, p. 275], [ref. 37, p. 2] and [ref. NR, pp. 18 & 20].} Figure 14. Sketch of the Waltham factory as it appeared in August 1858 (from Frank Leslie's Illustrated newspaper). It is speculative history as to how much inventory Howard and Rice took back to Roxbury. Wesley Hauptman reports that when Robbins, Tracy, and Baker took over, they completed and sold off the remaining Dennison, Howard & Davis movements. These watches had S/Ns 2601 to 5000 [ref. 10, p. 261]. Hauptman might have made this statement based on the serial number ledger "Record of Watches" [ref. 1]. His statement now appears to be incorrect. Although the ledger is evidence for the existence of these watches, it is not good evidence for determining which company actually had and sold them (see [ref. 100] Serial Number Ledger). One can conclude from the surviving DH&D watches that all movements 1001-5000 were produced (except maybe the last 100) [ref. 101, Statistical Analysis]. However, we cannot be certain how many were sold by the Boston Watch Co., Robbins' new company, or perhaps even Howard & Rice. Vern Hawkins' tabulation of sales records lists only about 120 DH&D movements sold by AT&Co through September 1857 [ref. 55, pp. 22-24] and confirmed in [ref. 62]. Additional DH&D movements could have been sold later, including watches pawned by Robbins [ref. 102], Sales Records. However, this is unlikely because by September 1857 Robbins was already producing more watches than he could sell [ref. 63, p. 590]. Based on the foregoing evidence (especially [ref. 101]) in regard to movements 4891-4910 in the insolvency records [ref. 106, case 116, sheet 153] and on a positive statement made by Curtis in his insolvency affidavit [ref. 106, case 116, sheet 180], it does not appear that more than perhaps a couple of hundred or fewer DH&D movements were sold other than by the Boston Watch Company, although possibly material for a few hundred DH&D movements with serial numbers in the range 4900 to 6,000 or so was cannibalized for AT&Co and H&R movements [ref. 63, p. 584] and [ref. 103, Serial Number Under Top Plate].

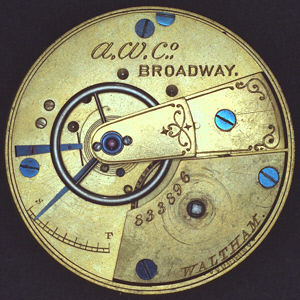

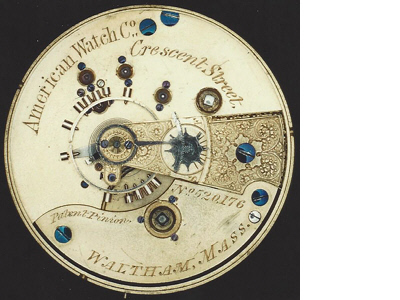

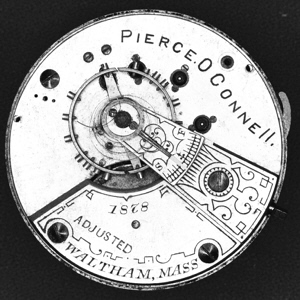

In addition to the question on the number of remaining DH&D movements, several references suggest Howard and Rice left very little to no unfinished material. E. Tracy says in [ref. 6, pp. 275-6] that, “Rice had taken all, or nearly so, the stock in the factory”, and that the company took several months to get reorganized. Percy Small reports that Howard and Rice removed the “movable goods” including work in progress, material and supplies, and a quantity of tools and small machines [ref. 13, p. 10]. Robbins is quoted as saying ".. I kept the factory going, principally in the construction of tools and machinery, till late in the year" [ref. 48, p. 22 in speach]. Moore shows a $33,000 Robbins’ entry in the Tracy Baker & Co’s May 1857 cashbook for the factory as “Machinery & tools”; note material is not mentioned. According to the Serial Number Ledger “Record Of Watches” [ref. 1], the first production did not start until July, 1857, and only 100 movements (AT&Co) were finished in the month. The Company therefore had nearly three months to produce these watches from raw material, which makes the “empty factory” argument plausible. Although as previously discussed, author believes Robbins did purchase some inventory material from Rice. Author points out that the insolvency inventory document [ref. 106, Case 116, Sheet 153], is titled account of stock in workmen's hands. His supposition is that finished goods would have been stored in a locked office (sales) area perhaps in a safe to which Howard and Rice would not have had access. The assignee Jameson would have had this area under "lock and key." This explains how Robbins had 120 or so DH&D movements to sell [ref. 102 Sales Records, Table 3]. How else could Robbins’ cache of DH&D movements be explained? Perhaps they were being held originally by the BWCo as collateral for a loan. Completed movements do not fit the definition of “material & work not finished” that Robbins bought from Rice. These movements were many hundreds in serial number below those cannibalized by Howard. So, Howard did not have them. Many DH&D movements survived with serial numbers between Robbins’ cache and those cannibalized by Howard. By serial number, the BWCo could have produced around 600 movements in this range. In fact, 10% have survived [ref. 101, Table 1]. The BWCo must have sold them. One could guess Robbins sold these movements privately and hidden from Company records, but that would be a very big stretch. Considering the vast research done on Howard & company, there has yet been any evidence that Howard sold DH&D movements, especially in significant numbers. Maybe a few movements he had but did not cannibalized, but not 600 movements. And note Charles Rice was not in the business of selling watches; according to Tracy he was a shoe merchant [ref. 6, p. 275]. Author provides explanation of these DH&D sales and details on how the leftover insolvency material was used in article titled Imagine Waltham Boston Watch Company movements in 6000s. He also believes the Boston Watch Company in Waltham was much more successful than most previous historians gave the Company credit. It looks like Howard and Rice kept all BWCo cases. There were, for example, 138 partially completed hunter cases in the February inventory. This makes sense because Howard kept the name. He used these cases to house H&R movements, as shown in the data tables and in [ref. 101, Table 2]. The author has yet to see any evidence of any BWCo case originally housing any AT&Co movement, but maybe we haven’t yet seen enough examples. The Appleton Tracy & Co. WatchContinuing Hauptman’s theme, the new company began finishing watches in the style of the Boston Watch Company and inscribed them with the trademark Appleton Tracy & Co. [ref.15, p. 690]; actually, the first movements were engraved Tracy Baker & Co. (at least twenty movements, 5001-5020, per [ref. 62, p. 4 for July 31, 1857]). Indeed, the Tracy Baker & Co. movement S/N 5012 has markings identical to DH&D movements except for the signature on the plate. So do movements e.g., S/Ns 5026, 5042, 5047, 5084 & 5086 (compare Figure 16 below with Figure 15 above).Looks like from the data tables the only embellishment Robbins gave his early movements was some gold balances (e.g., 5026); however, perhaps they would have been offered on DH&D movements if the BWCo had survived a little longer. Photographs in Figure 16 are by author; TB&Co 5012 with permission from Sotheby's October 9, 2004 NYC auction preview (the guard cup on the winding square is a replacement); AT&Co 5042 permission of Douglas Lynn. Details of the 5026 watch are given in the ATCo_5026 web page.

The AT&Co potance on the early movements is the same as employed on DH&D movements with its “new fastening method” (see data table at end of monograph), and the full four-digit serial number is stamped on the underside of the top plate as on DH&D [ref. 103], neither of which is the case on later movements. As seen in the data table, early AT&Co movements were predominately (if not all) 16J with the center pillar arbor being jeweled, whereas the DH&D movements were predominately 15J. Since Robbins strived to get product to market as soon as possible, author believes he hardly would have recut DH&D pillar plates for the 16th jewel; instead he believes high numbered DH&D movements not yet produced were intended to be 16Js. Figure 16A. New Markings on AT&Co Barrel Bridges From observation, AT&Co watches were typically fitted with sunk second dials, whereas the DH&D dials were smooth. Hauptman reported the first run of AT&Co watches have serial numbers 5001 to 8100 [ref. 10]. More specifically according to the Serial Number Ledger “Record Of Watches” [ref. 1], 5001 to 5200 include movements signed Tracy & Baker (see above paragraph), 6501 to 6590 are nameless/private label (but probably AT&Co grade), and 6901 to 8100 were not made. The AT&Co signature was retained as the quality grade for the full duration of the Model 57 product line which stayed into production through 1878. Vernon Hawkins’ production report lists 62,165 AT&Co grade Model 57 movements were made [ref. 54, p. 4]. The Boston Watch Company sold watches in the range of $30 to $50 with silver cases (twice this amount in gold) in 1856 [ref. 23], and Robbins held to this price in July 1857 for the Appleton Tracy watches (e.g., $24.50 for movements, $36.25 in silver hunter case, at 20% discount [ref. 62, pp. 4&5]). These watches were still rather expensive for their time. Twenty dollars was a month’s wage, for those who had wages (America was largely a barter society in the mid 1800s) [ref. 29, p. 1]. For another perspective, some brass clocks were selling for under $1 by 1855 [ref. 7, p. 270]. But the demand for moderately priced personal watches is what drove the industrialized watch industry. Although far from best at the time, AT&Co watches were of higher quality than their competitively priced foreign counterparts [ref. 63, p. 587], and 25% cheaper when measured quality for quality [ref. 64, p. 5].

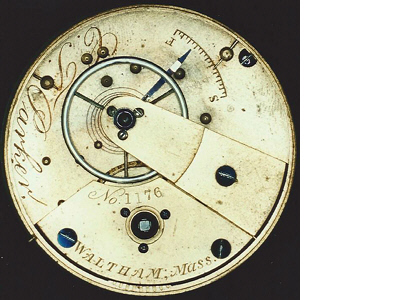

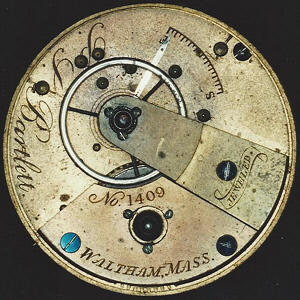

The C.T. Parker and P.S. Bartlett WatchesAlmost immediately after resolving his partnership terms with Tracy and Baker, Robbins began plying the “supply and demand curve” and started making lower grade watches. He introduced the 7-jewel C. T. Parker in November, 1857 [ref.1], for $16 (at 30% discount to retailer) [ref. 62, p. 23, sold Dec. 17, 1857]. In the next month, the P. S. Bartlett was introduced [ref.1] for $12 (30% discount) [ref. 62, p. 29, sold Jan. 13, 1858]. In observed examples the Bartlett appears identical to the Parker except the balance bridge was engraved. According to Hauptman, the Company ran short of plates to use on the Bartletts, so they used the full-jeweled AT&Co top plates which gave rise to the 11-jewel P. S. Bartlett watch, [ref. 15, pp. 696-7] which sold for $15 (20% discount) [ref. 62, p. 30, sold Jan. 27, 1858]. Harrold believes the 11J version was an intentional marketing ploy to give the appearance of a higher priced 15J movement [ref. 63, pp. 591-592]. This run of Parker watches have serial numbers 1001 to 1400; the Bartlett watches have serial numbers 1401 to 2200 [ref.1]. These watches were offered at much lower prices than the AT&Co grade, presumedly to increase sales, and in turn to compensate for lower margins. Although the BWCo offered some lower cost 7J DH&D movements (perhaps as an experiment [ref. 15, p. 695]), Robbins’ lower-grade watches were very distinctive. Figure 17. First Run C.T. Parker (S/N 1176) & P.S. Bartlett (S/N 1409), Forerunners of Company’s Commodity Products Regarding the differences between the prices of the C.T. Parker and P.S. Bartlett watches, the Parker might have been a better grade than the Bartlett, and the initial engraving of the balance bridge on the Bartlett was probably window dressing and/or an experiment to test customer acceptance. The Parkers were later engraved too, and the spelling out of the abbreviated full signature, “Chas (Charles) T. Parker”, on the second run movements indicates a better grade. Harrold suggests that the Bartlett was simply a price reduction ploy with lower margins, and the Parker was later upgraded to justify the price difference [ref. 63, pp. 591-592]. There is no obvious difference between the author’s first run C.T. Parker and P.S. Bartlett movements to justify a price differential, other than the Parker has a little better regulator (original?). These first-run so-called inexpensive models have their top plate pinned to pillar posts instead of being secured with screws; thus saving labor and costs as screw manufacturing had not yet become highly refined [ref.15, p. 697]. See examples in above figure. On the other hand, the pinned plates might have been an intentional distinguishing feature as these watches employed many other screws. The hairspring is anchored in a brass stud on the plate under the balance bridge on these watches, presumably hidden like this so the stud could be left unfinished and be less costly to produce (this subject is covered in the next chapter, see "Index Scale"). Although the C.T. Parker and P.S. Bartlett movements did not employ the same potance as on the AT&Co grade, they did share the same design of ratchet, ratchet bridge, click, and click spring. See “Features Not Tracked” in the next chapter. These design differences alone do not appear to justify the price difference (movements: ~$24 AT&Co, ~$16 Parker and ~$12 Bartlett; per [ref. 55, pp. 4-9 & 33-38]). Contributor Michael Edidin has an AT&Co advertising circular dated February 1858, which includes a price list with comparable prices (depending on jewel count and type of balance); however, the circular states that the Parker and Bartlett movements were not warranted whereas the AT&Co grade came with a “perpetual warranty”. Mike Harrold points out that Robbins used the AT&Co movement as the quality grade leader and the Parker/Bartlett movements as the common consumer watch. Although the common consumer might not afford the preferred AT&Co grade, he might find a way to purchase the lower grade. This successful merchandising technique launched the Company into a world-class manufacturing enterprise. Sales of the P.S. Bartlett Model 57 watches far exceeded the AT&Co grade watch [ref. 63, p, 589]. Hawkins estimates nearly 293,000 P.S. Bartlett Model 57 movements were made, 35% of the total Model 57 production [ref. 54, p. 4]. Incidentally, C.(Charles) T. Parker and P.(Patten) S.(Sargeant) Bartlett were highly valued employees at the Waltham plant in 1857. P. S. Bartlett joined the Company in 1855 at age 21 and became foreman of the plate and screw department in 1858 (his great uncle, Josiah Bartlett of NH, signed the Declaration of Independence) [ref. 49, p. 75]. Other than the honor of having their names used as trademarks, Parker and Bartlett received no compensation for the use of their names on movements [ref. 6, p. 276] and [ref. 104], Payrolls. An unexplained mystery is why Robbins used serial numbers starting with 5001 for the AT&Co movements and then skipped back to 1001 - 2200 for the C.T. Parker and P.S. Bartlett movements. These lower numbers are duplicates of the numbers on the DH&D watches produced at the Waltham plant by the Boston Watch Company and sold before the insolvency (or otherwise transferred to Robbins). Harrold suggests the juggled numbers was a subterfuge to allow disavowing the lower grade movements as old BWCo material in the event they were not well received [ref. 63, pp. 587 & 591]. On the other hand, perhaps the new company did originally plan to start anew with serial numbers. This would make the duplicate numbers more understandable (see [ref. 105]). A second run of C. T. Parker watches, signed Chas T. Parker, was produced in 1858. They have serial numbers 8101 to 8300. It appears from the data table, the entire second run was engraved with the abbreviated “signature” Chas T. Parker. The second run of P. S. Bartlett watches have serial numbers 8301 to 13700 [ref. 10] (except 11961 to 12000 may have some Bartlett & Parker inscriptions, and a few private label movements according to reference [ref. 1]). Based on observation, it appears these second run watches were a continuation of the lower grade watch designed to be more affordable, including pinned plates and the hidden hairspring stud, although the Parker appears to be a better grade than the Bartlett (probably to justify the price difference). The second run Chas T. Parker watches have a better finish than the Bartletts according to contributor Jon Hanson. Hawkins lists the second run Parkers as having mostly 15 jewels (Record of Watches [ref. 1] does not give the jewel count for these) whereas the Bartletts have 7 and 11 jewels [ref. 55, pp. 54-57]. The data table at the end of this monograph list 15J for Chas Parker. Pinned plates were continued on the Bartlett until late 1858 (around S/N 12500) according to the data table at the end of this monograph. Also as can be seen in the data tables, many Bartletts were fitted with 15 jewels, especially in later runs, but the 15J P.S. Bartlett was discontinued by end 1860, favoring the 11J instead for this grade according to the Serial Number Ledger [ref. 1] and to the P.S. Bartlett data table herein with an 1860 or later production date. These later run 15/11J movements were also made to look higher grade by engraving fake jewel settings into the top plate; the jewels in earlier versions were burnished into the plate with no special adornment. Figure 18.15J Chas T. Parker 8153 with real jewel settings and 11J P.S. Bartlett 8406 with burnished jewels Depression of 1857Sales looked promising up through September of 1857, then the depression hit the company hard [ref. 51, p. 29]. To get cash, watches were sold at auctions [ref. 6, p. 276] & [ref. 48, p. 23], and dumped at twice discount [ref. 51, pp. 32,36,&268] and [ref. 62, page 19; e.g., Oct 14 at 40%]; (also see [ref.102], Sales Records). Robbins was also able to arrange loans from wealthy Boston merchants through his contacts saying "... I deposited from time to time many boxes of watches in their State Street Banks [ref. 48, p. 23 in speach]. Employees were asked to work at half salary [ref. 15, p. 700]. By autumn 1858 the financial clouds began to break and a market for watches gradually emerged [ref. 47, p. 741].

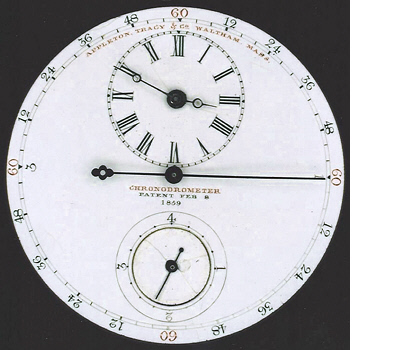

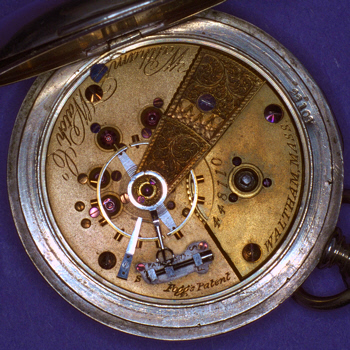

American Watch CompanyOn August 26, 1858, the Waltham Improvement Company agreed to merge with AT&Co [ref. 48, p. 23], and reorganized as the American Watch Company (AWCo) on January 1, 1859 [ref. 51 pp. 316-318]. The new name became official February 17 by act of Massachusetts Legislature [ref. 56, p. 29]. Robbins signed over the land and buildings to the Improvement Company a little earlier on August 13, 1858, for the same price and outstanding mortgages as when he purchased it [ref. 106, Deeds, Middlesex, Book 799, page 15]. Robbins retained his stock of watches in the deal which he withdrew from pawn and sold for " ... a moderate profit for the two years work" [ref. 48, pp. 23-24]. Harrold in [ref. 63, p 593] estimates Robbins stock of watches was substantial. Production under the new name started with serial numbers approximately 14000 [ref. 15, p. 698] (actually more like 15000 per [ref. 1]). The AT&Co name was retained as a trademark of excellence [ref. 48, p. 24]. In 1859 approximately 200 employees produced 50 watches per day; by 1883, 2,000 employees were producing 1,200 watches per day [ref. 51, p. 56] and [ref. 104], Payrolls. This production rate was now competitive with foreign manufacturers, and better. According to Cutmore, by 1883 the Swiss share of the American market dropped from virtually 100% pre’50 to 40% [ref. 59, p. 38] (although the English did have a significant market share with the Swiss in the 1850s [ref. 65, Nov. 13, 1857]). Producing consistently good quality watches, the American Watch Company actually provided protection for buyers of watches. Most first time purchasers knew little or nothing of watches at the time. They were at the mercy of deceitful dealers, who at best, dealt in foreign watches of highly variable quality irrespective of price, and who in many instances sold watches from irresponsible makers from across the ocean never to be heard from again [ref. 36]. Quoting New York Times, “It will be a cause of congratulation if this highly useful American enterprise shall have the effect of driving out of the market the thousands of trashy foreign articles, miscalled time-keepers, by furnishing so excellent and economical substitute” [ref. 64, p. 7]. The Chronodrometer WatchSo-called "sporting watches" (the chronodrometer stopwatch) followed the second-run P. S. Bartlett watch in serial number (13701; [ref. 1]). The stopwatch complication of the chronodrometer was built on the Model 57 design. A wire lever through the plate (at 8:30 in Figure 20 below, right) stops and holds the balance wheel when the stop button is pushed. The stopwatch, patent 22,914, February 8, 1859, by John K. Bigelow, was not very successful because, as pointed out by Hauptman, "The watch, while ingenious in its simplicity compared to foreign stopwatches, is highly impractical" [ref. 15, p. 697]. On the other hand, the limited sporting culture in America from 1858 to the mid-1860s probably had more to do with this timepiece's lack of popularity. Contributor Michael Edidin points out that although "Nicole patented the heart-shaped cam that is the basis of flyback chronographs in 1844," for many years afterward "the majority of sweep-seconds watches had stop mechanisms that stopped the whole train. The best known are the English center-seconds watches that were popular for 20 years or so, from 1880 to 1900. Robert Kemp has a good chapter on these in 'The Englishman's Watch.' But, even Kemp doesn't understand why these watches were so popular. Perhaps it had something to do with looking like a leisured sporting gent. The time for that in the U.S. was after the Civil War, not in 1860." According to the serial number ledger "Record of Watches" [ref. 1], material might have been allocated for the stopwatch chronodrometer in 1858-1859, but production stretched out through 1865.

The Model 1859 KW18 Watch

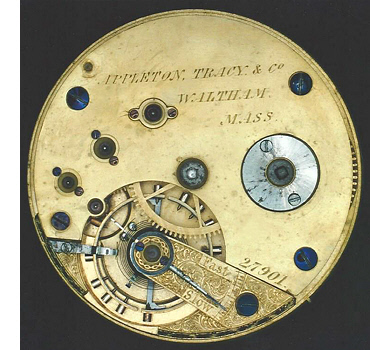

The serial number ledger "Record of Watches" [ref. 1] and reference [ref. 78] list the first M59 as S/N 28701. However, see Figure 21, at right, of AT&Co M59 S/N 27901! {photo permission of W. Ed Christiansen, Jr.} Author wonders if the movement wasn't misnumbered because according to "Record of Watches" 27901 is listed as a full plate AT&Co grade M57 made July 1860, right next to 27902 which is illustrated in Figure 36 in the next chapter. However, having serviced this watch, contributor John Wilson thinks it might have been a prototype for the Model 1859 movement. After acquiring the Nashua operation in the spring of 1862, and producing high-grade 16S and 20S watches out of the separate "Nashua Department" in the Waltham factory [ref. 27], the AWCo used the KW18 solely in lesser-quality 18S watches [ref. 29, p. 65], including a few P. S. Bartletts, but mainly William Ellerys [ref. 78, p. 44]. Up until this time, the full plate had been the most economical design to manufacture [ref. 29, p.44]. Figure 21. Thinner 3/4 Plate Model 1859 KW18 An interesting note is that the first ten KW18 watches are specifically listed in "Record of Watches [ref. 1] as being made by N. Stratton in November of 1859. This was just before Stratton left AWCo to cofound the Nashua Watch Company. The KW18 watches were deficient in design because ease of manufacturing had received a higher priority than excellence, which probably bothered Stratton and induced him and others to leave AWCo to produce a better-quality watch [ref. 27, p. 589].

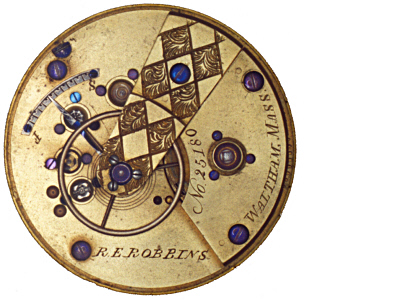

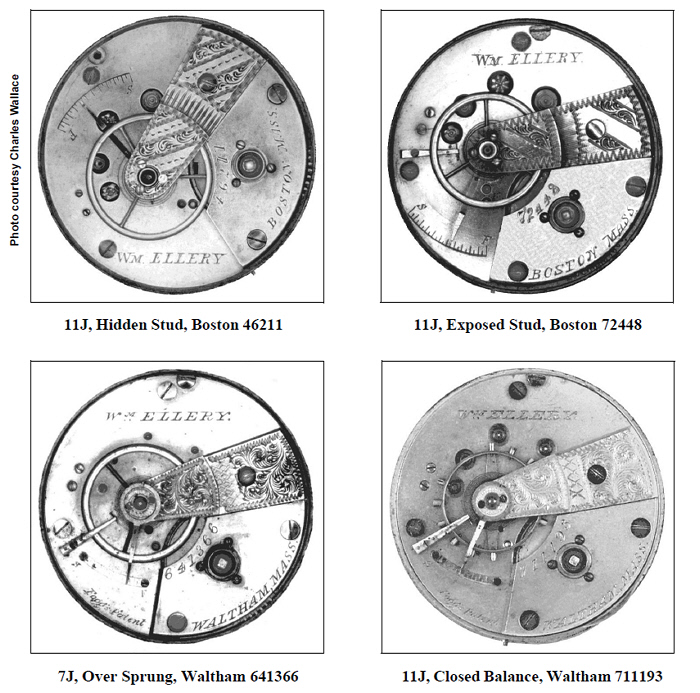

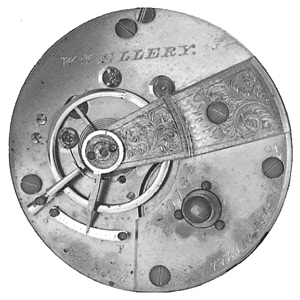

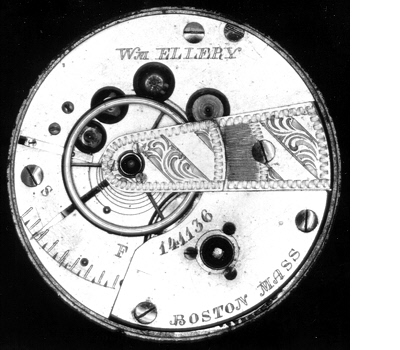

The J. Watson and R. E. Robbins WatchesIn 1859, Robbins still continued to experiment with Model 57 grades. Judging from appearance and data in the serial number ledger "Record of Watches" [ref, 1], the Chas T. Parker grade was followed by J. Watson and R. E. Robbins grades. First-run J. Watson watches have a unique engraving with the name "London" on the barrel bridge and have an English appearance (at least some do). The second-run watches all appear to be engraved "Boston" (see data table at the end of this monograph), perhaps to distinguish them from the P. S. Bartlett and to suggest they were not manufactured at Waltham. Several people have argued that these first-run Watson watches were probably made for export (e.g., see [ref. 58, page 134]; also see "J. Watson" in The Answer Box, NAWCC BULLETIN, No. 252, February 1988, p. 66; and, "Reply to Further Criticism of Fogg's Article" by Dr. Alfred E. Brain, of Timely Voices, NAWCC BULLETIN, No. 273, August 1991, p. 443.). Noting that these lower-grade watches had not yet received wide market acceptance at the time of their introduction, and that Royal Robbins of the American Watch Company was looking for ways to sell them in quantity, contributor Michael Edidin suggests another theory that this "London" engraving was an attempt to pass off the watches as English imports. The author points out that Robbins was in England in late 1861 [ref. 51, p. 45], whereas these first-run J. Watsons were made a year earlier which supports Edidin's theory. According to the serial number ledger "Record of Watches" [ref. 1], the first-run J. Watson movements (all 7J), S/Ns 23601-24300 were made from September 1859 through October 1860; the second run, S/Ns 28201-28700, were made from November 1860 through April 1861, including 11J versions. R. E. Robbins movements (all 11J) were produced with S/Ns 25101-25300 in September through November 1859; and with S/Ns 26801-27400 in November 1860 through March 186l. The R. E. Robbins movements appear identical to the P. S. Bartlett being produced at the same time, including under sprung hairspring, hidden stud, and fake jewel settings (just engraved into the plate). It is unclear why so few, or why any at all, were produced. Aaron Dennison, cofounder of the Boston Watch Company, was discharged from the company in December of 1861 for being a vocal dissenter and not following Robbins' instructions to focus on the ladies watch [2009 monograph published by NAWCC “Aaron Lufkin Dennison, An Industrial Pioneer and his Legacy” by Philip T. Priestley; pages 20-21]. Moore reports that Dennison was advocating the making of a cheaper watch to sell to the Civil War trade, and this is what got him in trouble with the company [ref. 51, pp. 45-46l. Dennison said the directors blamed him "for the results of their bad management" [ref. 39, p. 3]. Dennison retained his $10,000 in stock [ref. 37, p. 3] & [ref. 39, p. 3], and sued the company for breach of contract. The matter was eventually settled out of court in November 1863, with Dennison receiving $5,000 in back wages ($8,000 was requested [ref. NR, p.21]) and reversal of the discharge record [ref. 59, p. 32]. This author also believes by this time Dennison had made and sold a good number of James Russell pocket watches (see JR article). By this time the company's next marketing experiment, the Wm. Ellery grade M57 watch, had become the popular Civil War soldiers' watch, which vindicated Dennison's judgment [ref. 51, p. 47] and [ref. 18, p. 173]. Moore reports that ''by 1865 the soldiers' watch - the Ellery - accounted for 44.6 percent of unit sales and 30.4 percent of the dollar volume" [ref. 51, p. 49]. The Ellery serial number at the close of the war between the states was around 161000, according to the serial number ledger [ref. 1]. As variously reported, Dennison chose the name as being distinctive and also as one honoring one of the signers of the Declaration of Independence. Also, William Ellery was an abolitionist, and Dennison probably as well. However, because of the war market, this watch probably would have sold well under any name [ref. 18, p.174]. Frankly, this author is inclined to believe the idea that Dennison gave the Ellery watch its name is based simply on the coincidental fact that Dennison was the superintendent of the factory at the time; and the basis for the name is pure speculation. The serial number ledger [ref. 1] lists the Wm. Ellery as being introduced in May through August 1861, with S/Ns 42501 through 42800. The next run was in January 1862: 42911-43100. Hauptman reports that the first Ellerys start with S/N 46201 [ref. 18, p. 174], including some fifteen jewel movements. The author has yet to see any 15J M57 Ellery movements (per Hauptman), just 11J. According to the Ellery data table herein, very few of the first Ellerys seemed to have survived which is why Hauptman was seeing Ellerys starting at 46201. The barrel bridge on the earlier runs was engraved "Boston," perhaps to distinguish the Ellery from the higher-grade P. S. Bartlett watch and to suggest that it was not manufactured at Waltham. Later runs were equipped with closed (uncut) bimetallic composition balances to give the appearance of the higher-grade expansion balances then used on Bartletts (this subject is covered in the next chapter under "Balances"). See examples in Figure 24 below. Another example of a sprung over 11J Wm. Ellery (450166) with steel balance is shown in Figure 26 below in comparison with the Home Watch Co. grade M57. Hawkins estimates that nearly 212,000 Wm. Ellery Model 57 movements were produced, a quarter of the total Model 57 production; second to the P. S. Bartlett, but starting four years later [ref. 54, p. 4]. Dennison Pocket Watch CasesAs a side note, Aaron Dennison founded the Tremont Watch Company in 1864, but departed a couple of years later over a disagreement with the managers of the company. He immigrated to England in 1868, got involved with another watch venture in 1872 (the Anglo-American Watch Co.), then founded the Dennison Watch Case Company at the age of 62 [ref. 57, p. 15]. Manufacturing began at the end of 1874, with most of the output going to the London Office of the American Watch Company. The company was successful and became well known in the world jewelry trade. With this last venture, Dennison finally reaped the profits of his own inventive skills [ref. 32] and [ref. 35, p. 69]. Hallmarks on a silver case believed to be made by Dennison are shown below. Aaron Dennison used the AWCo managers’ hallmarks for his cases on American Watch Company movements probably because Robbins did not want to see Aaron’s hallmarks on AWCo watches sold in England [ref. 35, p. 72]. Very likely Dennison used this FFS hallmark on his early cases by Frederick Francis Seeland, assistant manager of AWCo office in London. Crescent Park and Martyn Square grade watches are covered further below. Additional examples of Dennison cases can be found in the Crescent Park/Martyn Square data table at the end of this monograph.

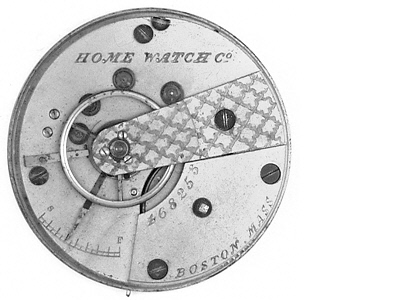

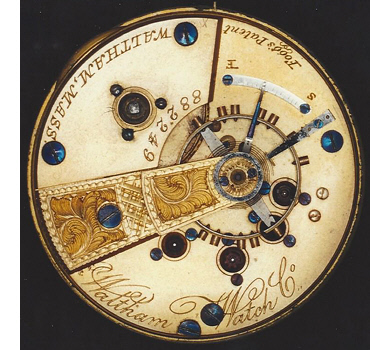

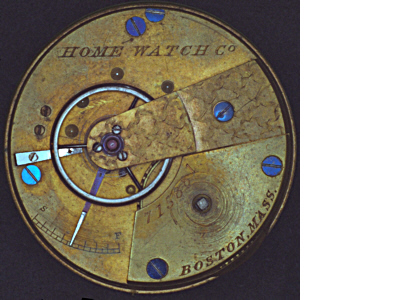

The Home Watch Co. WatchThe next low end Model 57, the Home Watch Company (HWCo) grade, was introduced in December 1866 with serial number 283001 with seven Jewels (the following January, 11 jewels were also offered) according to Serial Number Ledger [ref. 1], probably to compete with the newly founded National Watch Company. The barrel bridge was engraved "Boston" instead of "Waltham" possibly as camouflage to convey the impression that this watch was not made by the AWCo [ref. 18, p. 189]. The Wm. Ellery M57 was already engraved "Boston", and at this time was changed to "Waltham" (see data tables). These HWCo watches were characterized by steel balance, engraved index and no key guard protecting the winding square. Hawkins estimates 131,000 HWCo grade Model 57 movements were made, 16 percent of the total Model 57 production (very successful considering this grade started December 1866) [ref. 54, p. 4]. Author has data of 7J Home movements selling for $8 in 1867. About the time the HWCo grade was introduced, the Wm. Ellery grade was upgraded with a sprung over balance and an applied index strip. They were also offered with a closed (uncut) bimetallic composition balance to give the appearance of the higher grade expansion balances used then on P.S. Bartletts. See Wm. Ellery 711193 with closed balance in Figure 24 above. The Waltham Watch Co. Watch

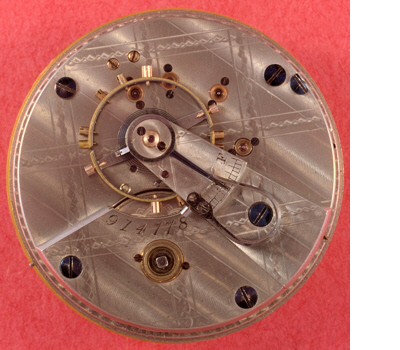

According to the data tables herein, all WWCo movements were given 15 jewels, but not quite all of the features of the AT&Co grade (e.g., jewel settings are fake, just engraved in the plate). It was provided with a stem wind even before the AT&Co grade, albeit not a very good one (probably because at the time the company was offering stem winds in models higher grade than the Model 57; "Stem Winds" are covered in next Chapter. Figure 27. Waltham Watch Co. Grade M57 882249 Upgrading the GradesAs Robbins introduced new Model 57 grades, he continually upgraded the existing grades with added features (e.g., as mentioned above with the Wm. Ellery). The AT&Co Model 57 movement shown in below picture was delivered in 1869 several years after the AWCo offered its better grade 3/4-plate models. Although no longer the company’s top offering, the AT&Co grade was the best in the Model 57 line. It was spruced up to look more like the 3/4 plates, but was offered at a more affordable price. Robbins was covering all bases. Note the plate jewels are smaller than on the earlier version and their settings are secured with two screws like the 3/4 plates versus three on earlier versions. Perhaps more important, the regulator and index were moved to the balance bridge like on the 3/4 plates. This was done only on the AT&Co grade Model 57 (not even the WWCo grade). Also note that the serial number is engraved on the plate on the AT&Co movement, whereas it is on the barrel bridge on all other Model 57 grades. The P.S. Bartlett (PSB) grade became Robbins’ mainstay Model 57, the middle ground grade, and was produced throughout the entire life cycle of the Model 57. As can be seen on the above 11J example made in 1869, it is fitted with an expansion balance like the two higher AT&Co and WWCo grades. Although there are exceptions (perhaps not original), the two lower Ellery and HWCo grades were not given expansion balances. Like the WWCo grade, the balance is sprung over and the jewel settings are fake on the PSB. By 1869, with the 3/4-plate models for people with money and these five varying grades of M57s (AT&Co, WWCo, PSB, Ellery and HWCo), Robbins was making a watch to match every taste and pocket book!

The Crescent Park and Martyn Square WatchesIntroduced in May, 1875, the Crescent Park and Martyn Square grades appear to have been made for export (at least as can be seen in the data table herein, many have surfaced in England - another successful Robbins experiment). Their style of engravings, balance bridge (with hairspring stud and wider base), and curved barrel bridge look like a cross with the full-plate Model 70 (shown later below), perhaps to be more acceptable to the English market. The balance bridge and barrel bridge on these export Model 57 watches are not listed in the “Waltham” 1885 Materials catalog. Perhaps these grades should not be called Model 57s, but they share most of the same parts, including the 4-pillar plates. A good number of Martyn Squares were made, mostly 7J and 2-pair 11J (about 16,000 per Hawkins [ref. 54, p. 4]). The Serial Number Ledger [ref. 1] lists Crescent Park as all 15J, S/Ns: 816801-890 (May - June, 1875), 816901-930 and 816941-960. Figure 29. 15J Crescent Park 816849 (left) and 7J Martyn Square 883390 Movements The Crescent Park and Martyn Square watch grades were undoubtedly named after locations in Waltham close to the factory; “Martyn Square, junction Crescent, Spruce and Adams, Ward 5” and “Crescent Park (C.P.) formerly known as Packards’ Island, Ward 6” (1893 Waltham and Watertown Directory, pages 34 & 38). Martyn Square is believed to have been dedicated to Waltham resident Henry Martyn a few years after his tragic death at age 38 in a swimming accident on August 24, 1871. Mr. Martyn was the popular Associate Director and Chief Accountant of the American Watch Company at the time of his death. Mr. R.E. Robbins was a pall bearer at his funeral (see related articles in the Waltham Free Press, August 25, 1871, and September 1, 1871, page 2, respectively). Thanks to England contributor, Philip Priestley, for ferreting out this information.

The Central Park WatchThe Serial Number Ledger [ref. 1] lists only 75 Central Park movements, S/Ns 842801-842875 (September to December 1875), as nickel movements. See data table at end of the Monograph: the eBay listing for S/N 842997 is outside this range, and the S/N Ledger lists it as a 15J stem wind nickel WWCo grade movement. The lack of information on this grade is a mystery.