Origins of the Waltham Model 57Design Changes in the Model 57by Ron PriceCopyright © 1995-2025originally published 2005 by NAWCC as Special Order Supplement No. 7 The Model 57 incorporated many improvements and changes during its 25 year history. Most of these features are recorded in the data tables and are described below in the order listed in the data tables. Many features are highlighted in picture below.

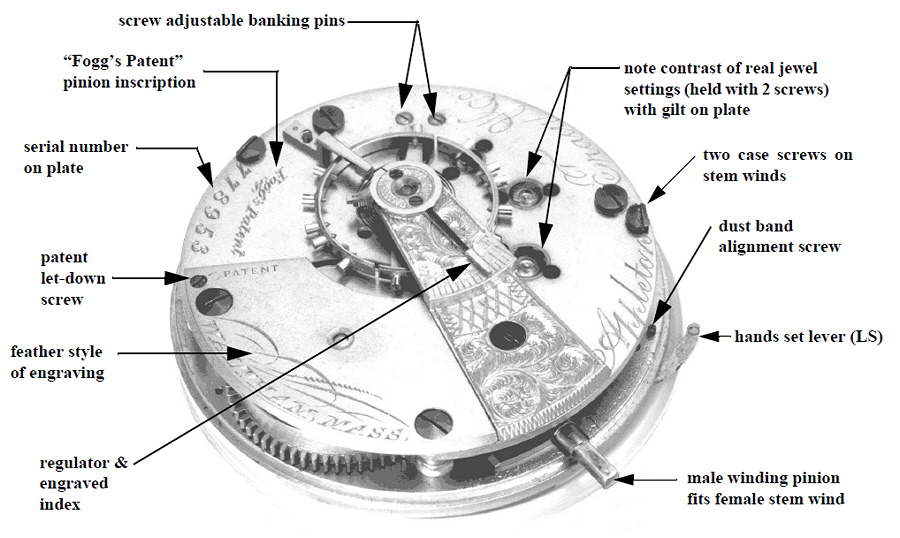

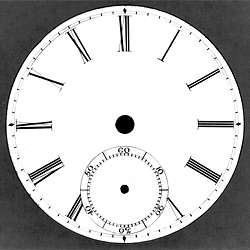

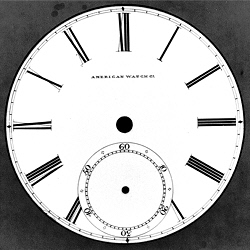

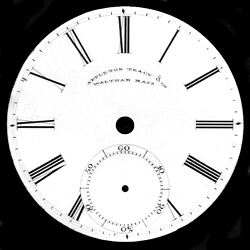

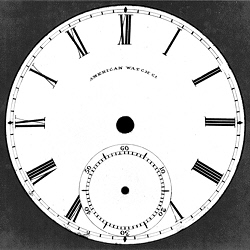

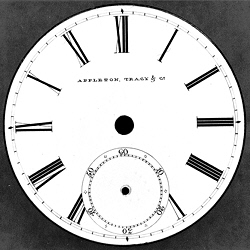

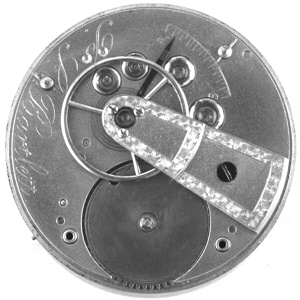

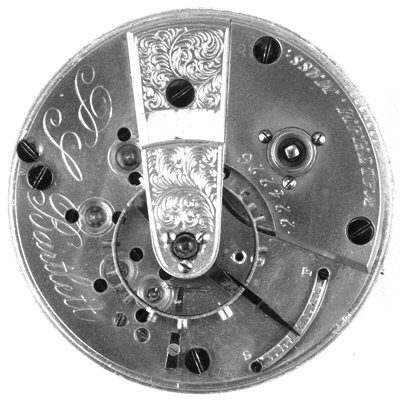

Figure 35. Appleton Tracy & Co Model 57 Stem Wind The following headings are in order by columns in the data tables; see the first page with legend of the data tables for definitions. Curiously, probably as an unique distinguishing feature, the American Watch Company began engraving serial numbers on the top plate instead of on the barrel bridge on AT&Co M57s movements (see above figure) starting probably in June of 1860 at S/N 27801 (along with the introduction of sprung over hairspring) according to the data table herein and the S/N Ledger [ref. 1]. The serial number was left on the barrel bridge on all other grades, including the Waltham Watch Co. grade M57. However, chronodrometers also had their serial numbers engraved on the top plate. Their production started earlier in October 1858. See [ref. 103] for more informaion with serial numbers. Note that the serial number in the data tables is indicated as to whether or not it is preceded with the abbreviation "No" if known. The City and State columns are self-explanatory. Interestingly, there were periods of times when the state-abbreviated "Mass" was not engraved on the barrel bridge on some grades, as can be seen in the data tables. The style of lettering varies from script to block letters to a wavy pattern, etc.; for example, see Figure 36 below for various AT&Co grade feature changes. Figure 36. Early Design Changes on the AT&Co. Grade Model 57 Note within this small range of serial numbers, 21792 to 27902, changes with engraving of serial number and Waltham/Mass; also hairspring changing from sprung under to sprung over. Indeed, it looks like (1) the position of serial number, (2) the dropping of the abbreviation "No", (3) the wavy style of engraving on barrel bridge, and (4) the introduction of sprung over hairspring all started for AT&Co movements in June 1860 at S/N 27801. The first dials were plain and not marked with a name until around serial number 6500 on the Appleton Tracy & Co. grade according to an early reference by Townsend, [ref. 41, page 34] but many earlier examples are listed in the data tables herein. From the data tables we can also see that standard dials have the Company name written out in full, typically in a straight line. Many dials were also written in a curved arc during the years 1865 to 1869 on P.S. Bartlett and WWCo grade movements. Progression of P.S. Bartlett dials is illustrated in Figure 38 below. Block lettering was typically used on the dials, but rare script examples exist as shown below. Other rare dials on early AT&Co. movements have Arabic numerals in a serpentine script style; e.g., see AT&Co. 22070 (CA 1859/60) identical with dials on the higher grade James Russell movements that look just like "Waltham" Model 57s; e.g. see JR 20145. See research article Who Made These James Russell Pocket Watches. Figure 38. Progression of P.S. Bartlett Model 57 Dials By observation of representative watches, seconds sunk dials were employed on most AT&Co movements, although not on their predecessor DH&D movements; perhaps this was a distinguishing feature (but then we do not have good data on the last DH&D movements made). Sunk seconds were also put on the Waltham Watch Co. grade; the introduction on other grades is listed in the summary Table 7 at the end of this chapter. Early on, dials must have been made outside the watch factory, probably as an independent operation because dials were not listed in the insolvency inventory documents. Michael Edidin has an Appleton, Tracy & Co advertising circular dated February 1858 where the Company was offering custom dials on order for $1.50 plus 50 cents for the name and another 50 cents for sunk seconds. Here is scan of the accompanying letter in lower part. Some high grade dials with Arabic numerals in a serpentine script style were made; see example AT&Co #6375 (Nov 1858). The AWCo was awarded a Bronze Medal at the Ninth Exhibition of the Mass Charitable Mechanic Association in Boston, September 1860, for "superior quality of the dials ...". This column in the data tables is used for tracking prominent features that have a limited time application. See Legend page.

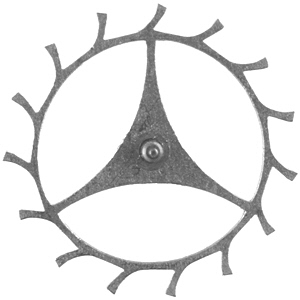

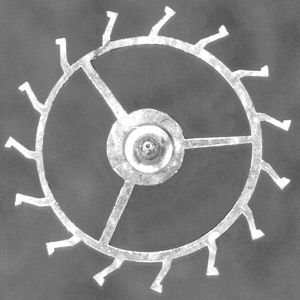

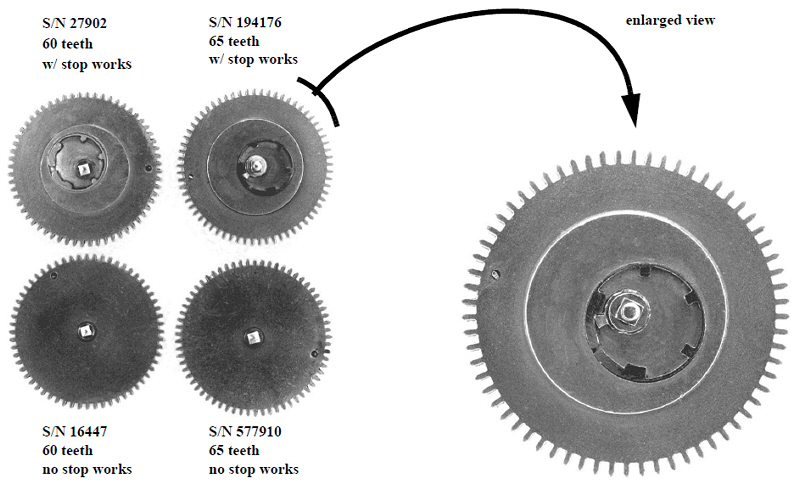

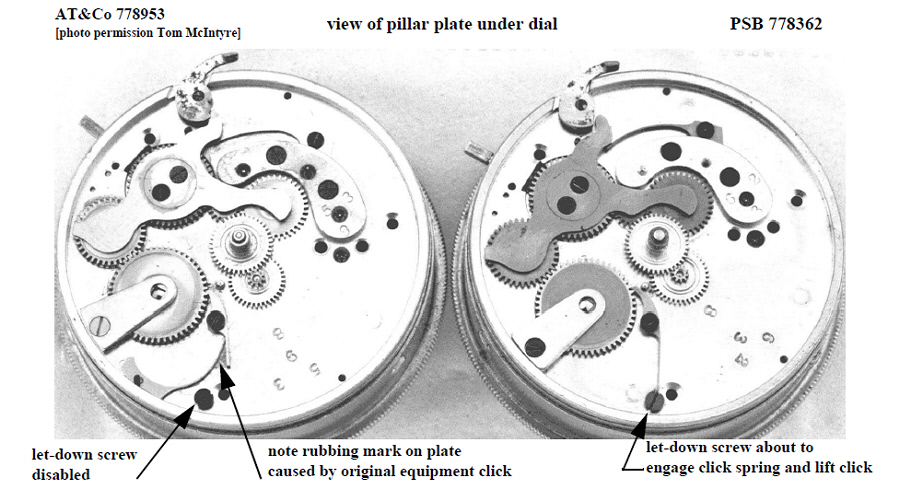

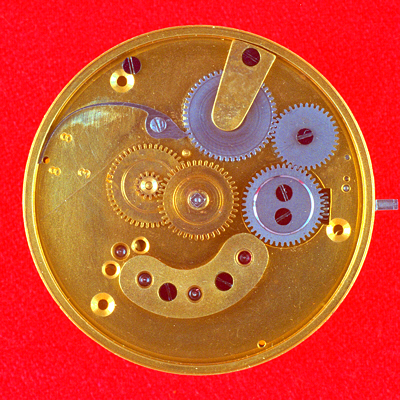

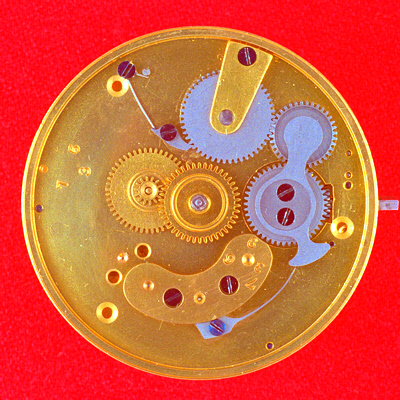

During the years approximately 1860 to 1870, the Appleton Tracy & Co grade Model 57 movement was equipped with stop works for the mainspring. The “Waltham” 1885 Materials catalog lists only the AT&Co, grade as having stop works. With stop works the mainspring is given a small amount of prewinding and the mechanism limits the amount of winding. The result is that only the middle portion of the spring is used to drive the watch which yields a more constant torque. The stop works employed on the Model 57 is hidden in a recessed section of the barrel on the pillar plate side. It is annular stop works like that found on a Chinese Duplex. By preventing over winding, stop works also reduces breakage which might be its main attribute, as reported by contributor Donald Dawes. As listed in the “Waltham” 1885 Materials catalog, the barrel for stop works has 65 teeth instead of the regular 60 teeth, presumably to compensate for the lower amount of uncoiling of the mainspring. Interestingly, though, the earlier stop-works barrel has 60 teeth (e.g., see AT&Co. S/N 27902). After 1870 the stop works were apparently discontinued, probably because mainsprings were of sufficient quality by this time to give constant torque, and perhaps because the stop-works barrel was difficult to remove from the movement and watchmakers were complaining (the plates have to be separated to remove the stop-works barrel because the arbor is longer and gets in the way; whereas on other movements the barrel can be removed simply by first removing the barrel plate and cock). For some reason, probably interchangeability (within the AT&Co. grade), barrels with 65 teeth were still continued to be put on AT&Co. M57s even without stop works (they did have the shorter arbor which simplified removal of the barrel). See Figure 39 below for four different barrel arrangements on AT&Co. M57s; pillar plate view is shown on Figure 40.

Figure 39. Four Types of AT&Co. Model 57 Barrels

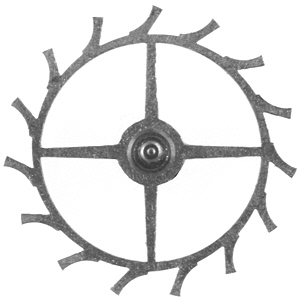

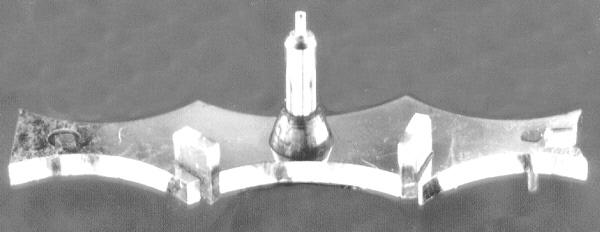

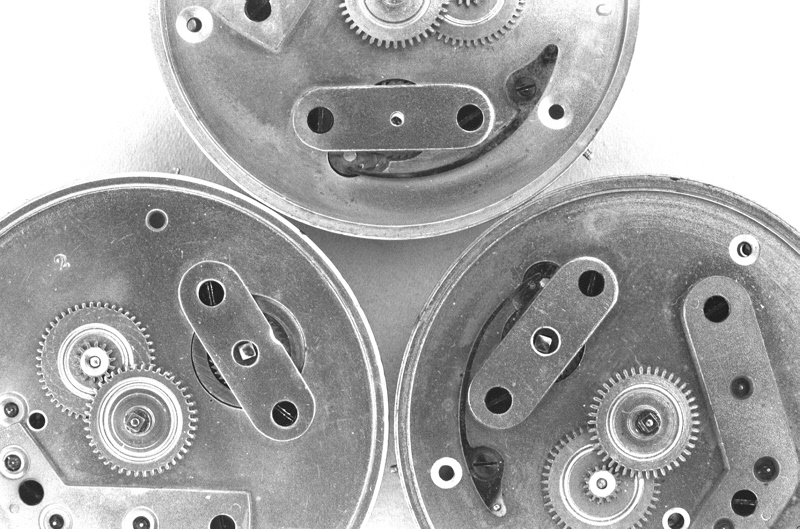

Figure 40. Three Types of AT&Co. Barrel Ratchet Arrangements Contributor Charlie Wallace reports that one way to see if a movement has a stop-works barrel is to slip a piece of heavy paper stock between the barrel and pillar plate to feel the built-up edge around the annular section of the stop-works barrel. Stop works is not supported if the bottom of the barrel is smooth up to the arbor. Another clue to recognize if the a watch has stop-works is to look at the ratchet bridge covering the ratchet and click on the pillar plate. With stop- works, the barrel arbor is longer and is given a rounded pivot end; then the hole in the ratchet bridge serves as a bearing hole for the arbor. Without stop-works the arbor is shorter and its end is squared off just to fit the ratchet; then the hole in the ratchet bridge is a little larger and the ratchet is visible through the hole. However, just to confuse collectors, the above statement is not true for the earlier stop-works movements which do not have the pivoted arbor (e.g., see AT&Co. S/N 27902). Three different ratchet arrangements are shown above. Figure 40 also illustrates two basic types of clicks employed on Model 57s. The left-most movement has a circular click surrounding the ratchet. Although this movement does not have a pivoted barrel arbor, later movements with the circular click do have the smaller bearing hole in the ratchet bridge if the watch has stop works. Later, a larger hole in the ratchet bridge with a visible square end arbor signifies no stop works. Aside from the barrel, stop-works consist of two parts, a male part that fits over the arbor and a female part in the recessed section (parts No. 167 and No. 168, respectively, in the “Waltham” Materials catalog). Incidentally, few stop-works survived the years. Probably many watchmakers pulled the stop-works out because they were a nuisance and were not really needed with the better quality mainsprings. Note that the male part of the stop- works on the arbor of S/N 27902 in Figure 39 above is so badly worn that it is inoperative. On the subject of ease with which the barrel can be removed from the movement, the plates had to be separated on the early movements because the top plate encircled the barrel (see Figure 41 below). This deficiency was corrected around 1859/60; e.g., see AT&Co 27902/43297, PSB 22622/22665, and J. Watson 23878 in the data tables.

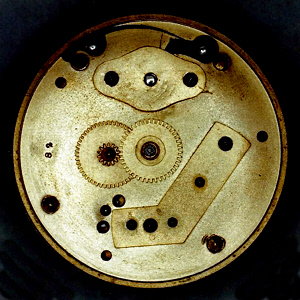

Figure 41. Top Plate Barrel Clearance Stem wind watches were offered on the Model 57 before this model was discontinued (see Figure 35 at the beginning of this chapter). The stem wind is listed in the 1885 American Waltham Watch Co.’s Materials catalog for the M57. According to the Serial Number Ledger [ref. 1], the first M57 stem wind was 15J Waltham Watch Co grade, S/Ns 555501-600 made Jul-Oct 1871, although American Watch Co. pendant winders were made as early as 1868 [ref. 48, p. 40] & [ref. 78, p. 14]. Other grades are listed in the summary Table 7 at the end of this chapter.

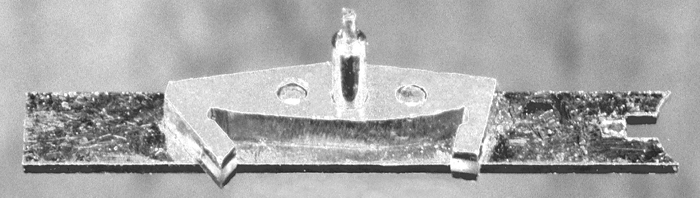

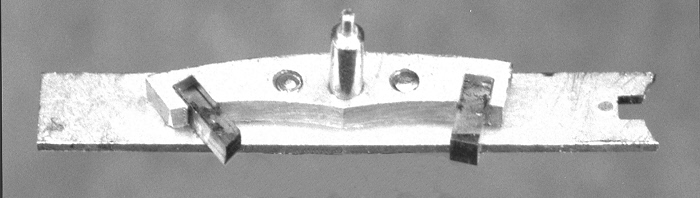

Figure 42. Click Let-Down on Stem Wind Lever Set Movements The standard winding and lever setting mechanism on Model 57 movements is illustrated in Figure 42 above. {Note: The convention used in this monograph to describe the sex of the stem wind is to associate it with the part in the case; however, the winding pinion on the movement is male on M57s.} The early stem winds with the lever setting mechanism were also fitted with a mainspring click let-down [ref. 82, p. 21]. The let-down screw appears at the edge of the barrel plate (see Figure 35) and the let-down mechanism is located on the pillar plate (shown in the right-hand photo on Figure 42 above). The main spring let-down is provided by this screw arrangement passing through the entire movement and out the barrel bridge for releasing the barrel click spring. The “Waltham” 1885 Materials Catalog lists this let-down screw and combined click-spring part for the SW let-down. This design was apparently unreliable and was phased out as can be seen in the data tables at the end of this monograph, where the let-down click spring is missing in later movements (shown in left-hand photo on Figure 42), and eventually even the let-down screw was removed (see Table 3 presented later). The “Waltham” 1885 Materials catalog lists these two click arrangements for stem wind. Although there are exceptions, the first M57 stem winds were still key set (SWKS) [ref. 18, p. 186], including 2nd run WWCo 597001-598000 made (per S/N Ledger) 11'71-12'73. See left picture below. Not only are these watches key set, the stem cannot be turned backwards (apparently to offer stem winding at minimum cost). Later Home Watch Co. grade watches were also produced as SWKS for lower costs (right picture below). The stem cannot be turned backwards on the left movement in above figure because there is no release for the ratchet. Note that the let-down spring has been removed [photo permission of Joseph Brown]. The winding train is not extended for setting the time on the right movement. Note that the let-down spring has been removed, but the lower spring releases ratchet when stem is turned backwards. Contributor John Wilson provided pictures of example 1st run and 2nd run stem wind WWCo movements. Shown below is 1st run WWCo 555592.

Note the stem cannot be turned backwards because there is no release for the ratchet. Although the let-down screw exists, the let-down spring is missing; instead a fixed spring holds down the ratchet pawl. Shown below is Wilson's example 2nd run WWCo 597534. It has the full let-down screw and spring assembly, plus a lower spring to release the ratchet so the stem can be turned backwards similar to the HWCo implementation in right picture of Figure 43 above.

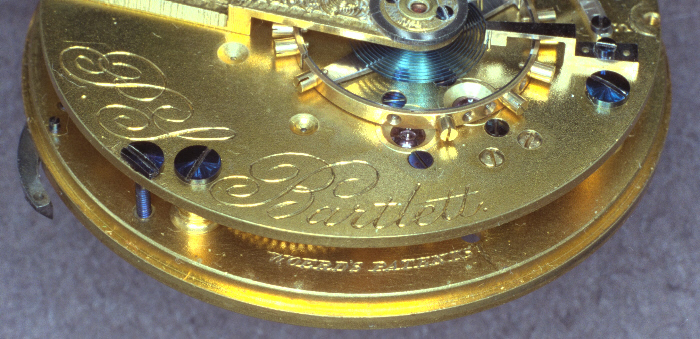

Also note the word "patent" next to the let-down screw on the barrel bridge is stamped whereas on the 1st run 555592 the word is engraved. Apparently the 1st run movements were originally intended to be key wind because a blue cap covers the mainspring arbor on the barrel bridge. It is a little different, but the blue cap is similar to the steel wind guard cup on early movements, and it replaces the brass wind guard cup. There is no blue cap or guard cup on the 2nd run movements. Marsh credits Charles Vander Woerd with remodeling the original 18 size full plate movements to incorporate a stem winding mechanism, but claims they were very unsatisfactory [ref. 48, p. 46]. We see shown in Figure 44 below the inscription “Woerd’s Patents” on the train side of the pillar plate on PSB stem wind S/N 778362. Two of Woerd’s patents were employed: (1) the rocking-bar winding/setting mechanism illustrated previously in Figure 42 (patent # 65,034, May 21,1867), and (2) the mainspring let-down feature described above (patent # 101,398, March 29, 1870). The “rocking-bar” mechanism was designed both for winding the mainspring and setting the hands.

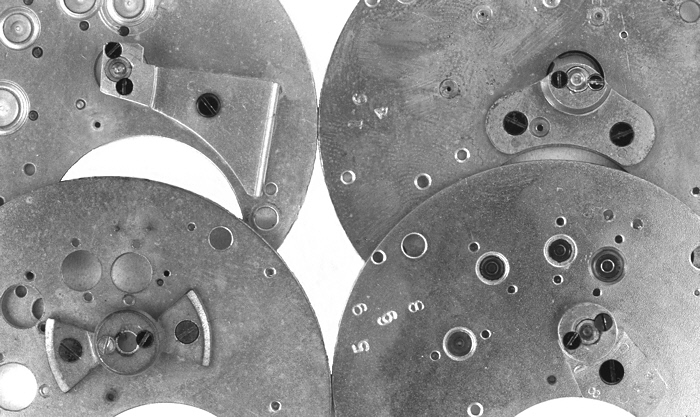

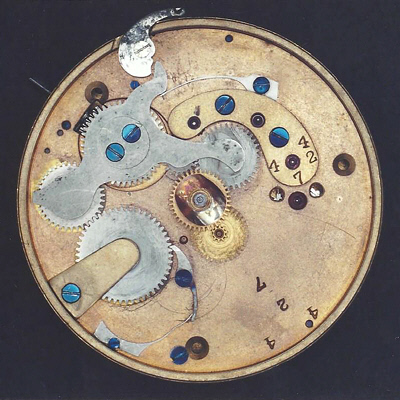

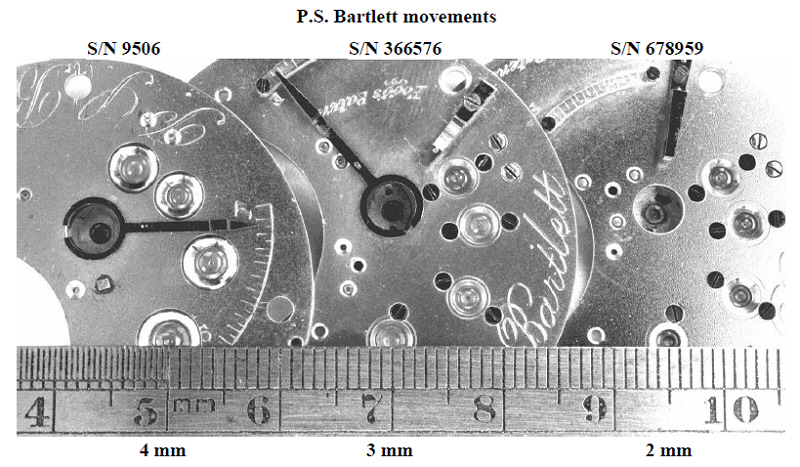

Figure 44. Inscription “Woerd’s Patents” On Train Side of SW Pillar Plate, S/N 778362 The “rocking bar” (or lever) was not Woerd’s patent; that was invented by A. Lecoultre in 1846. Woerd’s claim is that by hanging the fulcrum of the lever at the center of the wheel which is turned by the crown gear, the hands-setting mechanism is made entirely independent of the winding mechanism, and additionally the hands can be set in either direction. Robbins later hired Duane H. Church to design a better stem wind, which he did in the Model 83 that fits both open face and hunting cases (winding pinion on movement is female). Why the deficient transitional winding-only design was used many years after Woerd’s patent was available is unclear; perhaps the answer is simply that for marketing reasons the better stem winds were being offered at that time only in the better grades of watches. However (apparently to confuse future collectors), the factory built the full lever set “rocking bar” movements right in the middle of stem wind/key set serial numbers (200,000 numbers earlier) as typified by contributor Hugh Sanborn’s WWCo stem wind lever set movement S/N 597244! See pictures below. Sanborn's watch might actually have the intended full stem wind/lever set implementation. Consider this: contributor Irving Roth purchased (over this author) a SW/LS watch posted on eBay with number 1871 in December of 2002. As seen in the eBay picture of WWCo 1871, the word "patent" is engraved. The barrel bridge is an adapted plate from a period Appleton Tracy plate (with "feather" design). This movement (with some disrepair) signed WWCo sure looks like a prototype SW/LS watch, as Roth believes. Maybe someday the current owner will provide more information that will either confirm the watch is very likely a prototype or else is just a custom watch where the number "1871" is a coincidence. [It is listed in "Origins" custom data table.] In any case, the factory clearly experimented with various implementations for the early M57 stem wind watches. As can be seen from the data tables at end of this monograph, stem winds in P.S. Bartlett and Wm. Ellery grades were equipped with two pair of plate jewels for a total of 11 jewels instead of four top plate jewels (see above picture in Figure 44), but why only with stem winds when we can see early example above in Figure 45 with four plate jewels? Stem winds were also given two case screws versus the single screw on KW Model 57s (see above Figure 45 and Figure 35). The standard number of jewels on the Model 57 is either 7, 11, or 15. The Serial Number Ledger “Record Of Watches” [ref. 1] lists these as plain, 4 holes, 4 pairs, respectively. The eleven jeweled watch has four top plate jewels; although P.S. Bartlett and Wm Ellery stem wind movements have two pairs of jewels (2 pairs in [ref. 1] for a total of eleven) for some mysterious reason as can be seen in the data tables (see Stem Winds above). The early AT&Co. grade has the center arbor jeweled on the pillar plate (4 1/2 pairs in [ref. 1]) for a total of 16 jewels, whereas its predecessor, DH&D, does not, at least not predominately (but then we do not have good data on the last DH&D movements made, and see Sales Records reference [ref. 102]). The Howard & Rice watch is the same way. This 16th jewel is missed by many collectors, and a jewel count entry in the data tables of 15J for these watches is probably incorrect for early movements. Some custom “employee” M57 watches have 16 jewels, but the 16th jewel is on the top plate center (e.g., S/Ns 914778 and 933061 in the Custom Watches data table at end of this monograph). P.S. Bartlett and Wm Ellery watches are also often incorrectly reported as having 15 jewels instead of 11jewels. Only the early P.S. Bartlett watches had 15 jewels as mentioned above in the previous chapter on the P.S. Bartlett watch. According to Crossman, when the “Waltham Watch Co.” full plate movement was introduced, garnet plate jewels were used on the finer grades instead of the larger clear jewels [ref. 46, p. 30], although Hauptman points out that early Waltham Watch Co. grade movements actually came with aquamarine jewels [ref. 18, p. 191] (e.g., see examples in data table at end of this monograph). The garnet jewels have a red (maroon) vitreous (glassy) luster. See examples of translucent aquamarine jewels on AT&Co. S/N 5026 mentioned in previous chapter and on Hans Dahlke's PSB S/N 8406. An example of garnet jewels can be seen on WWCo. S/N 778362 in Figure 44. and also on WWCo. S/N 597244 in Figure 45. Smaller sizes of plate jewels were successively introduced with clear translucent jewels until garnet jewels were introduced. Just to confuse matters, the 1885 American Waltham Watch Co.’s Materials catalog in the M57 section lists “Chrysolite” (chrysoberyl [ref. 12, p. 197]) plate jewels for Appleton Tracy & Co., but both garnet and aquamarine jewels for the P.S. Bartlett (and Home, Wm. Ellery, & Waltham); note this catalog was issued after the last M57 was made. There seem to be three size categories: large, medium, and small (measuring the 3rd wheel back plate jewel (from the top in the plate) approximately: 4mm on the earliest movements, going to 3.5mm; 3mm for a period of time; then 2mm when the garnet jewels were introduced (see figure below). Jewel size is difficult to measure accurately in the plate on an assembled movement, but a good approximation (which is all we need here) can be obtained with a scale and loupe under good lighting.

Figure 46. Size Range Of Third Wheel Plate Jewel On Model 57s The PSB plate on the right side in Figure 46 above has the smaller garnet plate jewels, whereas the PSB in the middle has medium size clear translucent jewels. According to Crossman [ref. 46, p. 20] and others, the initially made aquamarine plate jewels were not very successful and had to be imported from England up until the time the factory was moved to Waltham. Crossman also describes how the jewels were set directly into the plates without settings. This information appears to be inconsistent with published photographs of very early movements (both Warren and Samuel Curtis) that show jewel settings (e.g., see examples referenced herein), unless Crossman was referring to later lower grade M57 movements. Although not an improvement, the employment of fake plate jewel settings should be noted. The Waltham Watch Co. and P.S. Bartlett grade watches have fake jewel settings engraved on their plates. The jewels are actually just burnished into the plate. Except for the predecessor DH&D movements and the early Chas. T. Parker movements, only the Appleton Tracy & Co. grade have real jewel settings. The fake settings can be easily recognized by observing that the fake setting’s groove is a much too perfect concentric ring and that the surface area of the fake setting looks the same as the gilded plate; indeed, on some P.S. Bartletts, the top of the B is engraved right through the fake setting. See Figure 47 below.

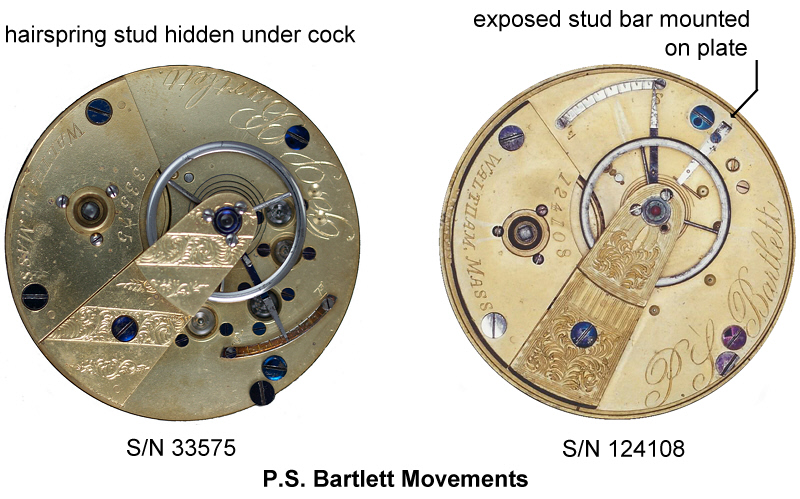

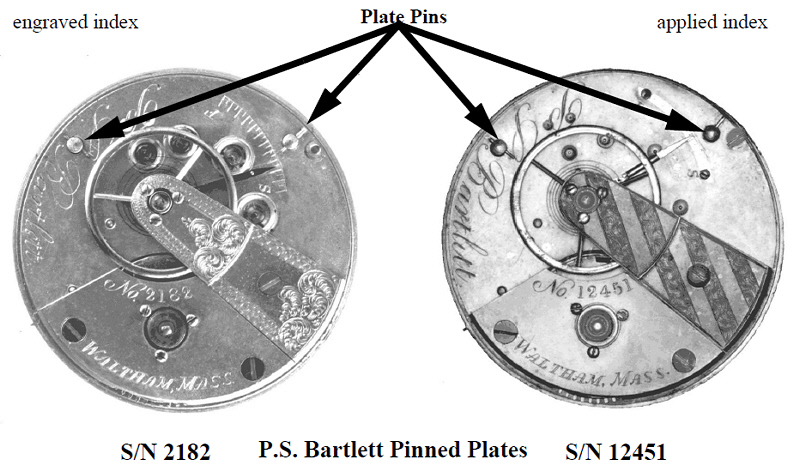

Figure 47. Fake Jewel Settings on P.S. Bartlett Model 57 The screws around the fake setting have no purpose other than decoration. A contrast can be seen between the real jewel settings and the plate surface in Figure 35. The early P.S. Bartlett watches are listed in the data tables herein as having no jewel settings, but they were engraved with a circular design that looks like a bezel. For example, see S/N 2182 in Figure 49 below and S/N 9506 in Figure 41 & Figure 46 above. Fake settings were apparently introduced just before serial number 11000 according to the data tables. Three screws were initially placed around the "settings" but changed to two screws around April 1865 (e.g., see PSB 160850). Real settings on AT&Co movements started with three screws but changed to two screws around end 1865 (e.g., see AT&Co 193548). All WWCo fake settings have two screws. The expense of engraving fake settings was not spent on the lower-grade Wm. Ellery and Home Watch Co. watches. The plate jewels on 11J versions are burnished into the plate without any decoration. See Wm. Ellery examples in Figure 24 in previous chapter. The hairspring stud is mounted on the plate under the balance cock on the early P.S. Bartlett movements (and all C.T. Parker movements), but later was move out to the side with a small bar attached to the plate. With this change, the regulator is swung around from the right side of the balance cock (looking down on it) to the left side of the plate (see figure below). Interestingly, the stud is in the outer position on the Samuel Curtis, Dennison Howard & Davis, and Appleton Tracy from the very beginning, indicating a higher grade.

Figure 48. Sprung Under Model 57 Hairsprings An index scale strip for the regulator was applied to later PSB plates to replace the engraved scale even before exposing the stud; presumedly the applied index scale was more important to customers than the stud and even pinned plates (see Figure 49 below) [picture of S/N 12451 permission of John Saby]. The scale was later engraved on the balance cock on AT&Co. movements (see Figure 35), but not on the other grades (except for export Crescent Park & Martyn Square movements), probably to convey the appearance of a higher grade movement as provided by the 3/4 plate movements that had been introduced by this time.

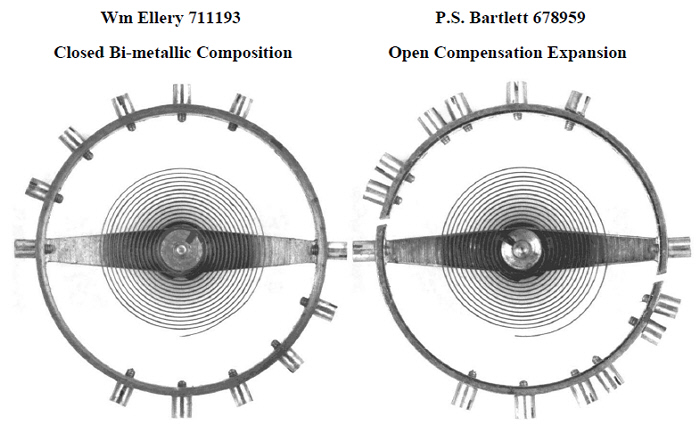

Figure 49. Sprung Under Hairspring with Hidden Stud The Serial Number Ledger “Record Of Watches” [ref. 1] lists the type of balance used by serial number. The first use of compensation expansion balances on Model 57s is listed in the summary Table 7 at the end of this chapter. Closed (uncut) bimetallic composition balances were used on the lower grade watches to give the appearance of the higher grade expansion balances (e.g., see figure below and the Wm Ellery data tables).

Figure 50. Composition Balances (Closed/uncut & Expansion) Several subtle differences will be observed on balances, even on same grade (e.g., thickness of rim, number and placement of timing screws on expansion balances). Author has collected some data on number of timing screws, but does not yet have any clear pattern to report. The S/N Ledger [ref. 1] does make a point of mentioning chronometer and “adjusted” balances {might be worth investigating}. Contributor Dick Ziebell pointed out the difference of the arm on early versus later expansion balances. The arm is wider and has a hole near the rim on early balances, but the opposite on later ones (e.g., compare the balance arms in Figure 35 with Figure 36). Dick believes the change occurred at the time of the introduction of the Nashua watches (e.g., Model 1860). The hairspring was sprung under the balance on all early grades of the Model 57. For example, see P.S. Bartlett sprung under movements in Figure 48 and Figure 49 above, and a sprung under AT&Co movement in the top photo of Figure 36. According to an introductory note in the Serial Number Ledger [ref. 1], the earliest sprung over Model 57 with the hair spring mounted above the balance arms was made March, 1865, on a WWCo. movement; AT&Co grade is not mentioned. Hauptman reports that sprung over balances were introduced in late 1868 [ref. 18, p. 189], but from observation the Appleton Tracy grade Model 57 was fitted with sprung over balances around June 1860 (see summary Table 7 at end of this chapter). The S/N ledger [ref. 1] lists movements 25301-25400) as nameless and ordered (at least one is signed AT&Co); the next AT&Co is 27801 which is probably sprung over (e.g., see 27822) along with the introduction of engraving the serial number on the plate versus the barrel bridge (see Position of S/N above). According to the PSB data tables, PSB movements were equipped with sprung over hairsprings sometime 1868/69 (e.g., see PSB 374616); roughly the same time for Wm Ellery movements. The regulator is mounted on the balance cock on sprung over watches instead of on the plates as on sprung under watches; also, the setting for the balance cap is held down with two screws on sprung over movements instead of three screws as on sprung under movements (see figure below and also Figure 36).

Figure 51. Sprung Under versus Sprung Over Hairspring (P.S. Bartlett movements) Quoting Hauptman, “The new way proved to be much better, as there was less chance of the spring rubbing either plate or the balance wheel and also it was far easier to adjust the collet if for any reason the watch got out of beat. This method of placing the hairspring over the balance wheel also enabled the use of the hairspring stud in the balance cock, which in itself was a great improvement and a boon to the watchmaker.” The Crescent Park and Martyn Square export grades took advantage of the studded hairspring (see Figure 29 in previous chapter; also see custom “employee” watch S/N 914778 in Figure 33A). Heat treated hairsprings were introduced in the 1870s. According to Michael Harrold the earlier hairsprings had more error than the benefit derived from temperature compensated balances at that time. References to tempered hairsprings being employed in Model 57 movements include: Home Watch Co. Model 57 ad in 1871 Waltham catalog reprinted in [ref. 82, p. 96]; an 1870s AWCo. newspaper ad says “Hardened and tempered hairsprings... are used in all grades of Waltham watches” [ref. 40]; also, the unique American Watch Co. grade movement S/N 38320 is described as having “tempered balance-spring” [ref. 77, p. 81]. By observing example movements, it can be determined that screw-adjustable banking pins (see Figure 35) were introduced about 1862 on all grades (see data tables at end of this monograph). The screw pins are also visible on the P.S. Bartlett in Figure 47 above. Crossman reports that Charles W. Fogg’s safety center pinion was introduced in 1865 and was adopted on all grades during the years 1866-7 [ref. 46, p. 30]. This feature unscrews the center wheel pinion in reverse direction when the mainspring breaks (see picture below), thus protecting the train from damage.

See “Fogg’s Patent” mark on movements in Figure 35, Figure 46 above and Figure 51 above. From observation, Crossman’s date appears to be about a year early for the Model 57. Charles W. Fogg’s patent safety pinion is patent No. 46,343, Feb. 14, 1865. This date is inscribed on the train side of the pillar plate, and the patent marking is inscribed on the top plate. An example inscription of the date is shown below in the left-hand picture of AT&Co. S/N 342887 (CA 03-05 ‘68) of Figure 53 below. The serial number of this watch is close to when the “Fogg’s patent” markings were begun to be applied. For more details see Evolution of the Safety Pinion by Craig O. Risch, NAWCC Bulletin, Whole No. 250, Oct. 1987, page 339. According to Serial Number Ledger “Record Of Watches” [ref. 1] and attached data tables, Fogg’s safety pinion was not employed on Model 57 watches until around 1867 per [ref. 1], or 1868 per the tables, two years after the patent. Why? Perhaps the safety pinion was installed on these watches but the plates were not marked accordingly. This does not seem likely, as the table on next page seems to confirm, because the safety pinion was worth advertising. {More movements in this time frame need to be examined because the center wheel with its pinion could have been replaced during a repair.} Competition from the National Watch Company in 1867 probably had something to do with this subject because the safety pinion (Fitts' or Fogg's?) was offered on the high grade 3/4 plate movements by January 1866 per the S/N Ledger [ref.1]. Table 2. Movements finished after Feb 14, 1865, that do not have the “Fogg’s” inscription

Also, Crossman’s reference [ref. 46] is before the lower grade Home and Broadway movements were introduced; they were not so equipped, but see below. Interestingly, the above right-hand picture of the date inscription of Fogg’s patent safety pinion is from a Home Watch Co. grade M57, S/N 749376. As can be seen from the data table at end of this monograph, HWCo movements were not equipped with the safety pinion until 1876, at least they were not inscribed with the Fogg’s patent marking. The Waltham 1865 Materials catalog did offer the safety pinion on Home Watch Co M57 movements (not Broadways, however). Why this watch has the date inscription but not the “Fogg’s patent” inscription is not clear. It does not have the safety pinion. Although it is a stem wind, it does not have the “Woerd’s Patents” inscription normally on stem wind movements as shown in Figure 44 above (however, it does not have Woerd’s “rocking bar”, only the let-down screw feature). The Fogg’s pinion patent date inscription seems to have been paired with the “Woerd’s Patents” inscription. The inscriptions were discontinued late 1875 or early 1876 when Woerd’s let-down screw was discontinued (as seen in Table 3 below). Table 3. Application of "Woerd's Patents" and Fogg's patent date inscriptions

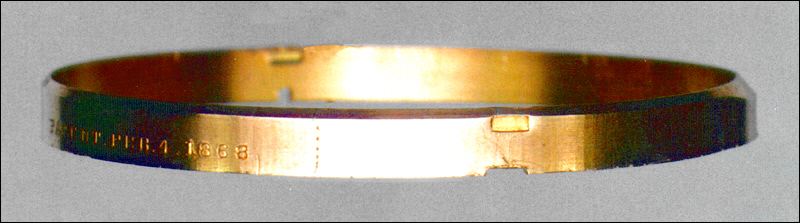

Dust bands were patented February 4, 1868, and the bands are so marked with the patent date (see picture below). See dust band alignment screw on AT&Co movement in Figure 35 which indicates movement was fitted at factory for a dust band.

Figure 54. Standard Model 57 Dust Band Dust bands appear to have been introduced much earlier than 1868 on P.S. Bartlett grade Model 57s as can be seen in the data tables herein. For example, PSB S/N 20944 has what appears to be a factory-fitted alignment screw on the pillar plate for the dust band although this movement was made in 1859 (it also has the hidden sprung under hairspring stud). See other pre’68 examples in listing; e.g., PSB 31885, PSB 32769, PSB 37881, and those listed below in Table 4 below. According to the data tables herein, the standard introduction of dust bands appears to be in 1867, earlier than the 1868 patent date. The reader should be aware that evidence of a factory dust band being originally on the movement is indicated by the presence of the dust band alignment screw (see Figure 35 ), or the hole for the screw, not whether the band is still on the watch. The seemingly early application of dust bands on P.S. Bartlett movements could be from watches being returned to the factory years later for repairs and the band was applied then, but there does seem to be quite a number of PSB examples, but not of AT&Co. grades (but maybe AT&Co. examples will surface someday). The dust band patent is No. 74,041, B.D. Bingham, February 4, 1868. It provides for a close-fitting, narrow (as possible) ring that is held in place without screws by two opposite indentations (“spurs”) in the ring. Slots are cut in the band, one under each spur (see above picture). One slot (foreground) is for prying the dust band off the movement with a screw driver, the other slot (background) slides over the alignment screw in the pillar plate. As explained in the patent, the spur which is above the wider “prying” slot has an inclined upper surface so that it easily snaps off the back plate when a screw driver is twisted upwards in the slot. The other spur over the “alignment” slot has a square shoulder which prevents the ring from rising (actually, the alignment screw is not mentioned in the patent). The dust band is quickly installed by positioning the band with its alignment slot to line up with the alignment screw and pressing this edge down first. Since dust bands were used before the patent on Model 57 watches, Bingham’s bands exist with a “patent applied for” marking; example donated by contributor Charlie Wallace shown below in Figure 55. Contributor Pat Caruso donated a plain dust band with a cutout for the alignment screw which appears to be held in place with friction [can we be certain it came from an early M57?]. Sample pre-1868 movements with the dust band alignment screw on the pillar plate are listed in Table 4 below that have been inspected for dust band screws on the back plate (they would look like small case screws with half heads).

The English-style side-lever escapement was employed on all Model 57 movements. However, the English-style pallets were replaced with the “Waltham” design around 1874 (by examining representative movements). The English pallets were so-called covered where the pallet stones are set in slots running in the plane of the pallet, whereas the Waltham (or American) pallet has its stones exposed which visibly stand out from the body of the pallet (see Figure 56 below). See introduction of the Waltham pallet in the summary Table 7 at the end of thios chapter, and in the data tables.

Figure 56. Right-Angle Model 57 Side-Lever Pallet

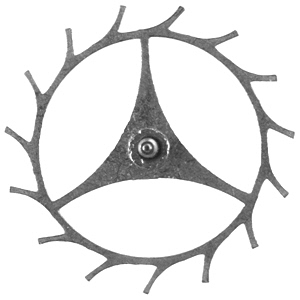

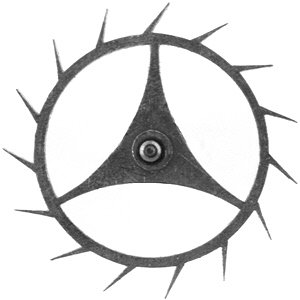

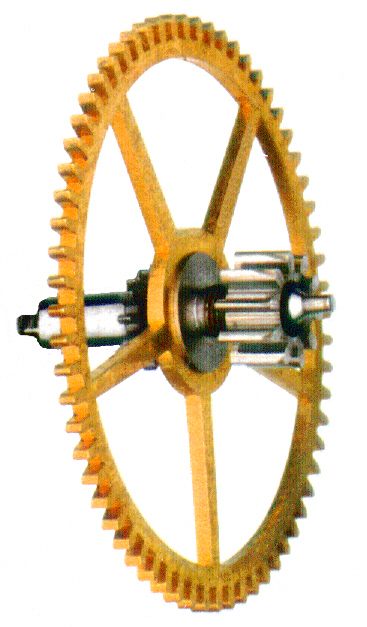

The initial escape wheels had pointed ratchet teeth which later were flattened at the ends a little because the pointed teeth were easily damaged through handling [ref. 46, p. 18]. The ratchet style eventually gave way to the full club tooth design to add an impulse face to the end of the tooth [ref. 82, p. 20] (see Figure 57 below).

Figure 57. Six Designs of Model 57 Escape Wheel References indicate that the club tooth was incorporated rather early on escape wheels (e.g., after several thousand movements were made; even Crossman [ref. 46, p. 18] says the club tooth was adopted at the time when the Waltham factory started operations). But the blunt-end tooth style of the early Model 57s could hardly be called “club tooth” compared with the later versions. Even the 1885 American Waltham Watch Co. Materials catalog does not list different types of escape wheels, yet the blunt-end style is illustrated for the Model 57, and the illustration is clearly different in other models. Ehrhardt in [ref. 82, p. 20] does point out the gradual change in the escape wheels, “with the higher grades making the change first.” There actually was an additional transitional design where the end of the blunt-end tooth is given a bit of a toe edge. The blunt-end design (especially the “toe-end” transitional design) is essentially equivalent to the full club tooth except the full club tooth gives more clearance for the drop. The four designs are illustrated above in Figure 57. The earlier escape wheels had the English design with three spokes which later was changed to four spokes (also illustrated in above figure). The club tooth escape wheel was employed on the “Nashua Model” design [ref. 27] which sets the time frame for this improvement at Waltham, Circa 1862; late 1863 for the AT&Co grade M57 according to the data tables herein. The reader should be aware of the difficulty in distinguishing between the four designs. Whereas the pointed tooth design can usually be determined simply by looking between the plates, and the club tooth can sometimes be determined the same way with good lighting and a powerful loupe, this method is generally not reliable. The best way, without disassembling, is to get closer by removing the dial and looking through the peep holes with good lighting and a good loupe. The above figure of escape wheels illustrates a 4-spoke TE escape wheel. This particular part might have been custom made as the author has seen no other example; this movement does have some (mixed) parts with different serial numbers. Interestingly, Howard & Rice movements were fitted with a club tooth escape wheel before the Model 57 per the data tables herein (see Figure 58 below [left picture permission of Bob Richards]). The shanks of Howard’s club tooth design on have a backward slant and look quite a bit different from the M57 club tooth escape wheel. Moreover, Howard & Rice movements were also fitted with pallets similar to the Waltham design many years earlier. The Howard pallet has large clear vertical jewels in the plane of the pallet (see Figure 59 below [right picture permission of Bob Richards]).

Click images for larger view, or here for contributor Jack Kurdzionak's escape wheel in color and lever in color from H&R #6282. The H&R escapement leads to questions. Did Howard redesign the escapement to make it better, or was the Boston Watch Company importing the escapement and Howard got them from a different supplier? The fact that Howard was experimenting with new designs very early on (e.g., see D,H&D 5000), including introducing quick train in the spring of 1858 while working under the settlement with Rice [ref. 13, p. 12] & [ref. 99, pp. 21-23], one could conclude that Howard did design his own escapement. The fact the early M57 escape wheels had the English 3-spoke design before changing over to a 4-spoke design supports the importing hypothesis. The common position is, though, that escapements were made at the Waltham factory. As described under The Bankruptcy in prior chapter, a February 2, 1857, inventory was taken of the Boston Watch Company factory. Escapement parts are listed in the inventory. Although Marsh does not specifically mention escapements in [ref. 48, p. 19] he says, “Several portions of the movements were procured from Europe such as: dials, hands, mainsprings, hairsprings, balances and jewels.” Contributor Edidin comments, “I don’t think that escapements for the early watches were imported. All the items on Marsh’s list, even hands, are specialized items that involve more than metal-cutting. Escapements are important enough to have made the list if they were imported, and they are just the sort of part that could be made locally. Styles of escape wheel would be influenced by experience with English watches and by exchange of ideas and techniques with travel.” Crossman in [ref. 46, p. 19] says BWCo’s third employee, James L. Baker, was their escapement maker, and describes the process of making pallets. A June 19, 1857, Waltham Sentinel article says Baker stayed with Robbins’ new company TB&Co [ref. 65]. Crossman goes on to say that balances were made by a Mr. Brown, an English balance maker who the Company hired to come to America to take charge of this work [ref. 46, p. 21]. Another comment, a reporter for the Waltham Sentinel wrote on March 13, 1856, about his observation during a tour of the factory conducted by the “foreman” Mr. Stratton. The reporter describes the making of watch hands in his article [ref. 23, p. 144]. Hauptman reports in [ref. 16, p. 929] that dial hands were imported at first, but a Mr. George Hastings was engaged just before the company moved to Waltham to make hands.

Features Not TrackedA number of changing features described in this monograph were not formally tracked in the data tables for a variety of reasons (including: “there were just too many”), and are listed here to be complete:

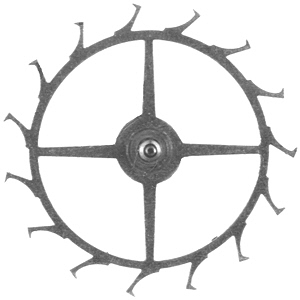

(see Figure 9, “Old and New Fastening Arrangements of DH&D Potances,” in prior chapter): Early movements incorporated a “U”-bridge shaped potance (including Howard & Rice movements), but this was quickly replaced with the standard M57 issue cantilevered design which evolved through three series as illustrated in the “Waltham” 1885 Materials catalog. See examples in the data tables herein and Figure 60 below. The “U”-bridge shaped potance was not employed on the C.T. Parker and P.S. Bartlett watches and was discontinued on the AT&Co grade probably before the second run as shown in Table 5 below.

Figure 60. Four Types of Model 57 Potances Table 5. The Change in the ‘U’-Bridge shaped Potance to the Cantilevered Potance part #215

Model 57 movements were introduced with the same style of ratchet, ratchet bridge, click, and click spring as on the DH&D movements (including the Howard & Rice movements). The long click spring attached to the edge of the pillar plate, the large comma-shaped click, and oblong ratchet bridge are illustrated below.

Figure 61. Pillar Plate Views of 1st Series Click and Spring Except for the ratchet bridge, these parts are listed in the 1885 Waltham Materials catalog for “1st Series” M57s. The "comma” click is part No. 231; the click spring is part No. 236. The oblong ratchet bridge is not listed in the catalog; in fact, the half-circle “1st Series” design (part No. 208) listed in the catalog has been seen by the author only on Warren #44, Samuel Curtis #212, and Samuel Curtis #899 (and on a John Warren movement #170 which is probably a custom “Samuel Curtis”), see Figure 10, “Progression Of Pillar Plates On The Curtis and DH&D” in previous chapter. The ratchet bridge and click were changed as the Model 57 evolved as illustrated in Figure 40, “Three Types of AT&Co Barrel Ratchet Arrangements,” the circular click (part No. 240) was next in line. Note that the (clam) click and spring in Figure 40 for the movements with the non-circular type of click (parts No. 232 & 237, respectively) are not quite the same as the similar parts shown above. Contributor Pat Caruso reported that the combined circular click and spring is fragile and breaks easily. As mentioned above with the Broadway grade, it, Home, and early DH&D watches did not have key guards. See Figure 30, “Example Home (715881) and Broadway (833896) Grade Model 57 Movements” in previous chapter. Steel guards were introduced on DH&D movements early in their production and continued on early AT&Co, C.T. Parker and PSB grades. See Figure 6, “DH&D Nos. 1016 and 2673”, Figure 16, “Three Early Movements from Robbins' factory in July 1857 (5012, 5026, 5042)” and Figure 17, “First Run C.T. Parker (S/N 1176) & P.S. Bartlett (S/N 1409), Forerunners of AWCo.’s Commodity Products”. According to the data tables, the steel cup was replaced with brass on AT&Co around Serial number 6000 and on the PSB around S/N 9000; both cups can be seen in Figure 49, “Sprung Under Hairspring with Hidden Stud”. Table 6. Train Speed of Different Movements with Count of Wheel Teeth and Pinion Leaves

According to Crossman, all 18S grades were converted to fast train by 1880, [ref. 46, p. 29]. According to references [ref. 78, p. 31] and [ref. 2], the last run of Model 57s was a Sterling grade S/Ns 1367501 - 1369000 (CA 1879/80) and they are listed with quick train (and stem wind); but this listing is likely incorrect. The 1885 AWWCo Materials Catalog does not offer M57 train wheels with different numbers of teeth, and see “Remaining Model 57 Watches” in previous chapter for further explanation. No examples are given here for the type of mainspring (but see [ref. 78, p. 5]). The T-end mainspring hook was introduced from 1862 to 1866 according to Hauptman [ref.18, p. 188], 1868 according to Crossman [ref. 46, p. 30]. The 1885 Waltham Materials Catalog page 106 does list the T-end mainspring (No. 2202) as well as the old style with brace (No. 2201) for stem wind Model 57s (No. 2201 was also used on key winds). Here is a trivia item. The style of lettering of the P.S. Bartlett was changed at some point in time. For example, the letter ‘l’ is open in early movements, but closed on later movements; the difference can be clearly seen between PSB S/N 260518 in Figure 47, “Fake Jewel Settings on P.S. Bartlett Model 57,” and PSB S/N 778362 in Figure 44, “Inscription “Woerd’s Patents” On Train Side of SW Pillar Plate”. And more trivia, contributor Chris Carey points out that the case screw on early movements were short, but later the screw was longer and screwed into the lower plate; this happened around S/N 400,000 (1869/70). And more, author found that the hair spring stud between two P.S. Bartlett movements with serial numbers 406849 and 579402 were not interchangeable. The index pins were different size. And there is a similar problem with case screws on early movements. So much for interchangeability.

Figure 62. Photo of Fitch Park from The Home of the Waltham Watch, 1911 promotional brochure. The initial isolation of the factory was a distinct advantage, permitting unrestricted development of ideal surroundings. The average person looking upon the system of parks, opposite and extending the entire length of the building, saw in them nothing more than a very successful attempt to please the eye. This was far from being the whole objective, however. The chief value of the planted grounds and sprinkled streets was in providing an almost dustless environment; somewhat analogous to today's "clean rooms" in semiconductor factories. Table 7. Summary Range of Serial Numbers at Which Feature was Introduced

Please note that the tables that follow here contain raw data; some mistakes can be expected from data entry and submitters. Use discretion. Look for patterns, not single examples. Interestingly, changing features usually follow serial number and not date of production (although there are exceptions); the reason is probably that material was reserved based on serial number and features were not retrofitted when the movement was actually made.The "Additional Notes" section at end of each table provides more details for a watch when available and appropriate, especially on cases. In this regard it is noted that the orientation of the head on eagle marks is recorded, but it is not always clear if the view is from the front or back of the eagle. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Figure 52. C.W. Fogg’s patented safety center pinion (pinion unscrewed in picture)

Figure 52. C.W. Fogg’s patented safety center pinion (pinion unscrewed in picture)